Embroidery adds a custom touch to clothing, hats, bags, and more. It uses thread to create designs on fabric. Many things affect the final price of embroidery. You might wonder what makes the cost go up or down. This article will explain the main factors that set embroidery pricing. We will look at common costs like custom embroidery cost, logo embroidery price, and the cost of embroidered patches. We will also cover special fees like the setup fee embroidery and explain how embroidery cost per stitch works.

Image Source: scalablepress.com

Deciphering Embroidery Costs

Think of embroidery costs like buying groceries. The final bill depends on what you buy, how much you buy, and where you shop. Embroidery pricing works much the same way.

No single price fits every embroidery job. It depends on several key things. These factors work together to set the price. Knowing these factors helps you understand quotes.

Let’s break down what influences the cost.

Stitch Count: The Main Driver

Most embroidery companies base their price on stitch count. What does this mean? It is the total number of stitches the machine makes for your design.

More stitches mean the machine runs longer. More stitches use more thread. So, a design with many stitches costs more than a design with few stitches.

Think of it like painting. A small simple picture takes less paint and time than a large, detailed painting. Embroidery is similar. A small logo with bold letters needs fewer stitches. A large, detailed picture with fine lines needs many stitches.

How Stitch Count Impacts Price

Companies often charge a price per 1,000 stitches. For example, they might charge $1.00 per 1,000 stitches.

If your design has 5,000 stitches, the stitch cost is $5.00 (5 x $1.00). This is just one part of the cost. Other fees add to it.

Finding the exact stitch count before getting a quote is hard. The embroidery company uses special software. This software counts the stitches in your design file. This is a key step in getting accurate embroidery quotes.

Grasping Embroidery Digitizing Cost

Before a machine can sew your design, it needs instructions. This is where digitizing comes in. Digitizing is the process of turning your artwork (like a logo or picture) into a special file.

This file tells the embroidery machine exactly what to sew. It tells the machine where to put each stitch. It tells it which color thread to use. It tells it when to cut the thread.

Digitizing is a one-time cost for each design. You pay this fee the first time you get a design embroidered. If you use the same design again on later orders, you usually do not pay this fee again.

Why Digitizing Costs Money

Digitizing is not automatic. It takes skill and time. A skilled digitizer looks at your artwork. They plan the best way for the machine to sew it. They decide the stitch types and sewing order. Good digitizing makes your final embroidery look great. Bad digitizing can make it look messy or pucker.

Digitizing costs can vary a lot. Simple text might be cheap or even free. Complex logos or detailed images cost more.

- Simple text or basic shapes: $15 – $40

- Average logo: $35 – $75

- Complex logo or detailed artwork: $75 – $150+

Some companies offer free digitizing. This often comes with larger orders. Or the cost might be hidden in the item price. Always ask about the digitizing fee upfront. It is a big part of the custom embroidery cost, especially for first orders.

Setup Fee Embroidery Explained

Besides digitizing, you might see a setup fee embroidery charge. This is separate from digitizing. This fee covers the time it takes to get the machine ready for your specific job.

This includes:

* Loading the design file into the machine.

* Hooping the garment (putting it in a frame).

* Loading the correct thread colors.

* Running a test stitch to check everything.

Some companies include this in the price per item. Others list it as a separate line item. Like digitizing, this fee is often per design. If you embroider the same design on 50 shirts, you pay the setup fee once.

Setup fees can range from $10 to $30 per design per location. For example, putting a logo on the chest and text on the sleeve might mean two setup fees.

Design Complexity and Size

How complex is your design? How big will it be on the item? These things directly affect the stitch count.

- Complexity: Fine details, small text, gradients (color blending), and lots of different elements mean more stitches. A simple block letter logo is less complex than a detailed coat of arms.

- Size: A larger design naturally needs more stitches to fill the space. A 3-inch logo uses fewer stitches than a 6-inch logo.

A complex, large design will have a high stitch count. This increases the embroidery cost per stitch part of the bill. It might also increase the digitizing cost.

Number of Colors

The number of colors in your design can affect the time it takes. An embroidery machine can hold many colors of thread (often 9 to 15). If your design uses colors already in the machine, it sews quickly.

If the design needs colors not in the machine, an operator must stop the machine. They must change the thread spool. This takes time.

Some companies might charge a small fee for many color changes. Or they might not charge extra for standard numbers of colors (like 6-9). Discuss your color needs when asking for embroidery quotes.

Garment Type Matters

What are you putting the embroidery on? The type of item matters.

- Easy items: Polo shirts, t-shirts, sweatshirts, hats. These are common and easy to hoop.

- Harder items: Jackets (especially thick or lined ones), bags with many pockets, items with strange shapes or seams. These take more time and effort to hoop correctly.

- Delicate items: Silks, thin materials. These require special care to avoid damage.

Items that are harder to work with may have a higher price. This covers the extra labor and time needed. A jacket might cost more to embroider than a simple t-shirt with the same design.

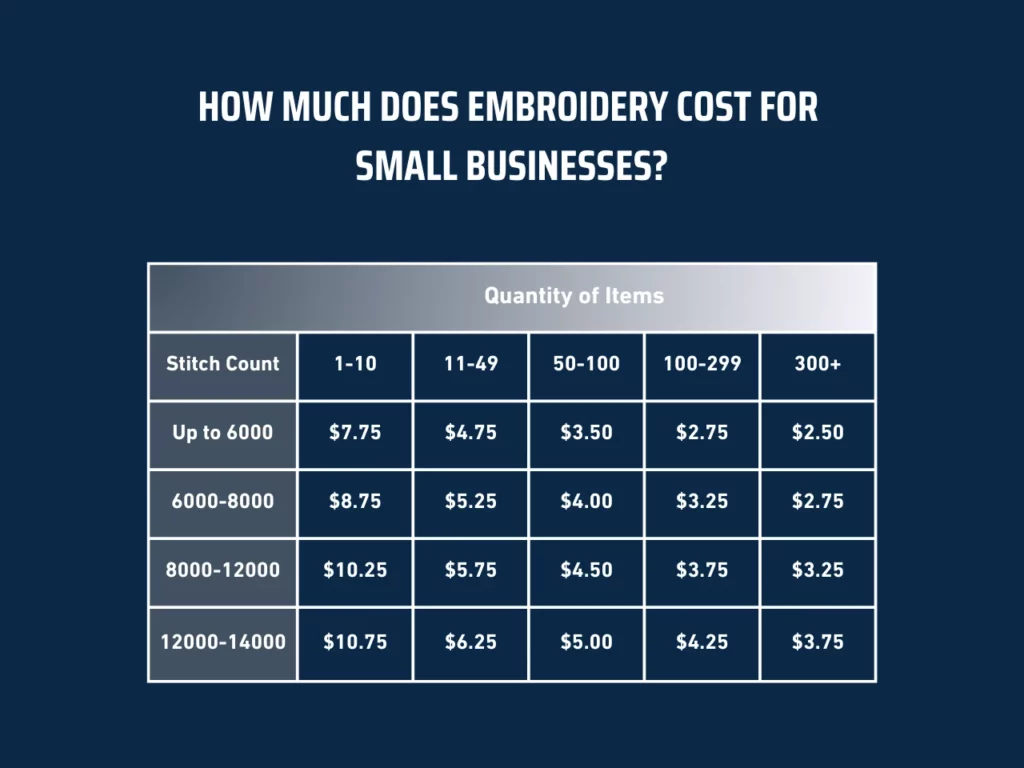

Quantity: The Bulk Embroidery Discount

This is a big factor in embroidery pricing. The more items you get embroidered, the lower the price per item usually is.

Why? Because the initial steps (digitizing, setup) are fixed costs. They don’t change if you order 1 item or 100. When you order many items, these fixed costs are spread across more pieces.

Also, machines are set up to run many items at once. This is more efficient. The labor cost per item goes down on large orders.

Companies almost always offer a bulk embroidery discount. The price break points vary. You might get a better price at 12 items, 24 items, 50 items, 100 items, etc.

- Ordering 1 item: Highest price per item.

- Ordering 24 items: Lower price per item.

- Ordering 100 items: Much lower price per item.

If you need many items, always ask about price breaks. This is key to getting the best value for your custom embroidery cost.

Thread Type and Special Threads

Most embroidery uses standard polyester or rayon thread. This is durable and comes in many colors.

Sometimes, you might want special threads.

* Metallic thread: Adds shine. It can be tricky to work with. It might increase the cost slightly.

* Glow-in-the-dark thread: Fun for special projects. Also can cost more.

* Fire-resistant thread: Needed for safety wear. Costs significantly more.

Using standard thread keeps costs down. Special threads add to the price.

Different Kinds of Embroidery and Their Costs

Embroidery is used in many ways. The cost can differ depending on what you need done.

Custom Embroidery Cost

This covers any embroidery done specifically for you. It uses your unique design. This is the most common type of service.

The cost will include:

* Digitizing your design (first time).

* The base price per item (often based on stitch count).

* Setup fees.

* The cost of the blank garment or item.

A simple custom embroidery on a polo shirt might cost:

* Digitizing: $50 (one time)

* Setup: $20 (one time)

* Embroidery: $5 – $10 per shirt (depends on stitch count)

* Polo shirt: $15 – $30 (depends on quality)

If you order 1 shirt: $50 + $20 + $5 + $15 = $90 total.

If you order 24 shirts: $50 (digitizing) + $20 (setup) + (24 x $6 embroidery) + (24 x $15 shirt) = $70 + $144 + $360 = $574 total.

Price per shirt: $574 / 24 = $23.92 per shirt.

See how the per-item cost drops significantly with quantity? Custom embroidery cost is lowest per item when you buy in bulk.

Logo Embroidery Price

Logo embroidery is a common type of custom embroidery. Businesses, teams, and clubs use it often. The price follows the same rules.

The main factors for logo embroidery price are:

* Stitch count of the logo.

* Number of colors in the logo (less impact usually).

* Item being embroidered (hat, shirt, jacket).

* Quantity ordered.

* Digitizing cost (one time for the logo).

A standard size chest logo (around 3-4 inches wide) might have 5,000 to 10,000 stitches.

Example logo embroidery price breakdown per item (assuming digitizing and setup paid):

* Small order (e.g., 12 shirts): $7 – $12 per shirt (embroidery only)

* Medium order (e.g., 50 shirts): $5 – $9 per shirt

* Large order (e.g., 200 shirts): $3 – $6 per shirt

These prices are for the embroidery work itself. You add the cost of the shirt or item to this.

Monogram Embroidery Price

Monogramming is embroidering initials or a name. It is often much simpler than a complex logo. Monogram embroidery price is often lower per item.

- Simpler digitizing: Initials in a standard font are easy to digitize. Some companies have pre-digitized fonts. This might mean low or no digitizing cost.

- Lower stitch count: Initials or a name have fewer stitches than a large logo.

Monogramming might be priced per item with no separate stitch count breakdown. Or it might be a low flat rate per name/initials.

Example Monogram Embroidery Price:

* Digitizing (if needed for a special font): $0 – $30

* Setup: $0 – $15

* Embroidery: $5 – $10 per item

Monogramming is usually faster for the shop. This helps keep the price down compared to detailed custom designs.

Cost of Embroidered Patches

Embroidered patches are different from direct embroidery. Direct embroidery is sewn right onto the garment. A patch is sewn onto a separate piece of fabric first. Then the patch is attached to the item.

Patches have extra steps:

* Embroidering the design onto patch material.

* Cutting the patch shape (often with a special machine).

* Adding a backing (like iron-on or velcro).

* Attaching the patch to the final item (sewing or heat press).

Because of these extra steps, the cost of embroidered patches is often higher per design than direct embroidery.

Patch costs depend on:

* Size of the patch.

* Stitch count of the design.

* Complexity of the shape.

* Type of backing.

* Quantity ordered (significant bulk discount).

Example Cost of Embroidered Patches (patch only, not attached):

* Small patch (2-3 inches, simple): $2 – $5 each in bulk (100+)

* Medium patch (3-4 inches, average design): $3 – $7 each in bulk (100+)

* Large or complex patch: $5 – $10+ each in bulk (100+)

Small quantities of custom patches are much more expensive per patch. Ordering just one or a few patches can be $15 – $30+ per patch before attachment.

Attaching the patch to an item is an extra service. This adds to the final price of the item.

Comprehending Pricing Models

How do embroidery companies calculate your total cost? They use different models.

Per Stitch Pricing

This is the most common way. They determine the stitch count of your design. Then they multiply the stitch count (usually in thousands) by their rate per 1,000 stitches.

- Formula: (Total Stitches / 1,000) * Rate per 1,000 stitches + Digitizing (first order) + Setup + Item Cost

Example: 8,000 stitches, $1.20 per 1,000 stitches, $60 digitizing, $25 setup, item cost $18.

* Embroidery cost: (8,000 / 1,000) * $1.20 = 8 * $1.20 = $9.60

* Total for 1 item: $60 + $25 + $9.60 + $18 = $112.60

* Total for 24 items: $60 + $25 + (24 * $9.60) + (24 * $18) = $85 + $230.40 + $432 = $747.40

* Price per item (24 quantity): $747.40 / 24 = $31.14

The rate per 1,000 stitches can vary. It might be $0.80 to $1.50 or more depending on the shop, complexity, and quantity.

Flat Rate Pricing

Some companies might offer a flat rate per item for very simple jobs. This is common for:

* Names on shirts.

* Simple monograms.

* Small, basic logos under a certain stitch count (e.g., under 5,000 stitches).

They might say, “Any name embroidered is $8 per shirt.” Or, “Any logo under 6,000 stitches is $7 per hat.” This is simpler for the customer to understand.

Tiered Pricing

Many companies use tiered pricing. The price per item changes based on the quantity tier you reach.

Example Tiered Pricing (Embroidery only cost):

* 1 – 11 items: $10 per item

* 12 – 23 items: $8 per item

* 24 – 49 items: $6 per item

* 50 – 99 items: $5 per item

* 100+ items: $4 per item

This clearly shows the bulk embroidery discount. Remember, digitizing and setup are often extra for the first order.

Interpreting Your Embroidery Quotes

When you ask for embroidery quotes, the company will send you a price. This quote should list the different costs clearly.

Look for these items in a quote:

* Digitizing Fee: Listed as a one-time charge for your design.

* Setup Fee: May be listed per design or included.

* Embroidery Cost Per Item: This might be a flat rate per item, or the quote might explain the stitch count and the rate per 1,000 stitches.

* Item Cost: The price of the blank garment or item you are buying through them.

* Total Cost: The final price for everything.

* Breakdown by Quantity: Prices per item should change as quantity increases.

Always ask questions if you don’t understand the quote. Make sure you know if the digitizing is included or extra. Ask if setup is charged per order or per design.

Additional Factors That Affect Cost

Besides the main points, a few other things can change the final embroidery pricing.

Small Text and Fine Details

Embroidery machines sew with needles and thread. Small letters (under 0.25 inches tall) and very fine lines can be hard to sew clearly. They require more stitches in a small area. This can increase stitch count. It also requires more skill in digitizing and running the machine. Some shops may charge slightly more or have minimum letter heights.

Multiple Embroidery Locations

Do you want a logo on the chest and text on the sleeve? This counts as two separate embroidery locations. Each location needs:

* Its own digitizing (unless the designs are identical).

* Its own setup time and fee.

* Its own stitch count added to the total.

Embroidering multiple locations significantly increases the cost per item.

Rush Orders

Need your items fast? Most companies charge a rush fee for jobs needed sooner than their standard turnaround time. This can add 25% to 50% or more to the total bill.

Specialty Backing or Hooping

Some items need special backing material to make stitches lay flat. Some need special frames (hoops) to hold them. Thick fabrics, stretchy fabrics, or unusual items might need this. This can add a small extra cost.

Factors That Help Lower Costs

While some things raise the price, others help lower your custom embroidery cost.

Ordering in Bulk

As mentioned, the bulk embroidery discount is the biggest way to save money per item. Plan your orders to maximize quantity.

Simple Designs

A clean, simple design with clear lines and shapes costs less. It has a lower stitch count and is easier to digitize and sew.

Providing High-Quality Artwork

Give the embroidery company a clear, high-resolution image of your design. Vector files (like .ai, .eps, .svg) are best. This makes digitizing easier and more accurate. Poor quality images can increase digitizing time and cost.

Being Flexible with Garment Type

Choosing standard, easy-to-embroider items like polo shirts, t-shirts, or standard baseball caps can keep costs down.

Planning Ahead

Avoiding rush fees by ordering with enough lead time saves money.

Cost Examples

Here are some rough examples of typical embroidery pricing ranges. These are just estimates. Actual prices will vary based on the factors discussed.

Example 1: Simple Logo on 24 Polo Shirts

- Design: Small, 3-inch, 2-color logo (approx. 6,000 stitches)

- Quantity: 24 shirts

- Item: Standard pique polo shirt ($18 each)

| Cost Item | First Order (per item) | Re-order (per item) |

|---|---|---|

| Digitizing | ~$60 (one time) / 24 = $2.50 | $0 |

| Setup | ~$20 (one time) / 24 = $0.83 | ~$20 (one time) / 24 = $0.83 |

| Embroidery (@ $1/1000 stitches) | (6,000/1000) * $1 = $6.00 | $6.00 |

| Polo Shirt Cost | $18.00 | $18.00 |

| Total Per Item | ~$27.33 | ~$24.83 |

Example 2: Monogram on 1 Item (e.g., Gift)

- Design: 3 initials in a standard font (approx. 2,000 stitches)

- Quantity: 1 item

- Item: High-quality bath towel ($30)

| Cost Item | First Order (per item) |

|---|---|

| Digitizing | ~$15 (could be $0) |

| Setup | ~$10 |

| Embroidery (@ $1.50/1000 stitches or flat rate) | ~$8.00 (flat rate common for names/initials) |

| Towel Cost | $30.00 |

| Total Per Item | ~$63.00 |

Note: For single items, the fixed costs (digitizing, setup) are a much larger part of the total.

Example 3: Complex Logo on 100 Hats

- Design: Detailed, 3.5-inch logo (approx. 12,000 stitches)

- Quantity: 100 hats

- Item: Standard baseball cap ($10 each)

| Cost Item | First Order (per item) | Re-order (per item) |

|---|---|---|

| Digitizing | ~$90 (one time) / 100 = $0.90 | $0 |

| Setup | ~$25 (one time) / 100 = $0.25 | ~$25 (one time) / 100 = $0.25 |

| Embroidery (@ $0.90/1000 stitches for bulk) | (12,000/1000) * $0.90 = $10.80 | $10.80 |

| Hat Cost | $10.00 | $10.00 |

| Total Per Item | ~$21.95 | ~$21.05 |

These examples show how quantity, design complexity (stitch count), and the item price greatly impact the final per-item cost.

Comparing Direct Embroidery vs. Patches

When deciding between direct embroidery and embroidered patches, consider these cost points:

| Feature | Direct Embroidery | Embroidered Patches |

|---|---|---|

| Digitizing | Needed for the design | Needed for the design |

| Setup Fee | Needed per location per run | Needed for the patch production run |

| Embroidery Cost | Based on stitches on the item | Based on stitches on patch material |

| Material Cost | Cost of the garment/item | Cost of the patch material + garment cost |

| Extra Steps | Hooping the garment, sewing | Sewing patch, cutting, backing, attachment |

| Cost per Design (Embroidery Only) | Generally lower for same stitch count | Generally higher due to extra steps |

| Cost per Item (Finished Product) | Can be lower, especially for simple jobs | Often higher due to patch making & attachment |

| Flexibility | Permanent on item | Can be removed/replaced (if attached with hook/loop) |

| Use Cases | Logos on shirts, hats; monograms; designs integrated into fabric | Uniforms (removable ID); retail items (tags); bags; complex shapes/edges |

While the embroidery itself might be cheaper per stitch on a patch run, the extra steps for patches often make the final cost higher than direct embroidery. However, patches are useful for certain needs or looks.

Getting Accurate Embroidery Quotes

To get the best idea of your final cost, contact several embroidery companies. Ask them for embroidery quotes. Provide them with detailed information.

What to include in your request:

1. Your Design: Send a high-quality image file. Tell them the desired size (width or height) for the embroidery. Mention if there are any specific colors (Pantone colors are best if you know them).

2. Items to be Embroidered: Tell them what items you need. Specify the type (polo shirt, hoodie, cap, bag). If you are providing the items, tell them the material and any specific details (like if hats have a seam down the front). If they are providing the items, ask for their catalog or options.

3. Quantity: Give the exact number of items you need. Ask for quotes at different quantity levels if you are unsure (e.g., 24, 50, 100).

4. Location: Tell them where you want the embroidery placed on the item (e.g., left chest, center back, sleeve).

5. Deadline: Let them know when you need the finished items. Mention if you require a rush order.

6. New Order or Re-order: Specify if this is the first time using this design or a repeat order.

Getting detailed embroidery quotes from multiple shops lets you compare prices and services. Don’t just look at the bottom line. See how they break down the digitizing, setup, and embroidery costs. Ask about their turnaround time and revision policy for digitizing.

Fathoming Value Beyond Price

The lowest price is not always the best deal. Quality matters in embroidery. Poor digitizing or poor sewing can ruin a design. It can also ruin the item you are embroidering on.

Consider the company’s reputation. Look at examples of their work. Read reviews from other customers.

A slightly higher price might mean:

* More experienced digitizers.

* Newer, well-maintained machines.

* Better quality threads and backing materials.

* Skilled machine operators.

* Better customer service.

These things add value. They help ensure your final product looks professional and lasts a long time. When comparing embroidery quotes, weigh the price against the perceived quality and service.

Frequently Asked Questions (FAQ)

-

What is the cheapest way to get embroidery done?

The cheapest way is usually to order a simple design on standard items in a large quantity. Avoid complex designs, special threads, or rush orders. -

Is digitizing a one-time fee?

Yes, usually. You pay the embroidery digitizing cost only the first time a specific design is used by that company. If you take your digitized file to a different company, they might charge you again or require re-digitizing. -

Do all companies charge a setup fee?

Not all companies list it separately. Some include the setup time in their per-item embroidery cost or have a minimum order fee that covers it. Always ask for clarification on embroidery quotes. -

How can I estimate the stitch count of my design?

This is hard to do accurately yourself. The embroidery company’s software does this precisely. However, you can guess based on size and detail. A simple 3-inch logo might be 5,000-8,000 stitches. A complex 4-inch logo could be 10,000-15,000 stitches or more. -

Can I bring my own items to be embroidered?

Yes, many companies allow this. Be aware that they may charge more for this service. They take on risk if they damage your item. Some may not guarantee items you provide. -

Does the number of colors affect the price much?

For designs with a reasonable number of colors (e.g., under 12), the effect on embroidery pricing is usually minimal. It might add a tiny bit to the time if thread changes are frequent, but stitch count and quantity are much bigger factors. -

Is it cheaper to get patches or direct embroidery?

For the same design and quantity, direct embroidery is often cheaper per item than patches. Patches require extra production steps (making the patch) and often an extra step to attach them. -

What is the typical turnaround time for embroidery?

Standard turnaround time varies. It can be 1-3 weeks from approving the design and quote. Rush orders cost extra to get items faster.

Embroidery adds lasting value and a professional look. By understanding how embroidery pricing works – from stitch count and digitizing to quantity and item type – you can get accurate embroidery quotes and make informed choices for your custom embroidery cost.