Yes, you can absolutely refill your sewing machine bobbin with thread! It’s a fundamental skill for any sewer, essential for consistent stitching and successful projects. This guide will walk you through the entire process, from selecting the right bobbin to properly winding it, ensuring you’re ready for any sewing adventure.

Image Source: i.ytimg.com

Why Bother Winding Your Own Bobbins?

Many sewers wonder why they need to wind their own bobbins when pre-wound ones are available. While pre-wound bobbins can be convenient, winding your own bobbin offers several advantages:

- Cost Savings: Buying thread by the spool and winding it yourself is almost always cheaper than buying pre-wound bobbins.

- Thread Choice: You have complete control over the type, color, and brand of thread you use. This is crucial for matching thread to your fabric and project needs.

- Thread Quality: You can ensure you’re using high-quality thread that will hold up well in your projects.

- Consistency: Properly winding your own bobbin ensures consistent tension and thread delivery, leading to neater stitches.

- Urgency: When you run out of a specific color or type of thread mid-project, filling a bobbin yourself is often the quickest solution.

Essential Tools for Bobbin Winding

Before you begin how to thread a bobbin, gather these essential tools:

- Sewing Machine: Of course!

- Bobbin: Make sure it’s the correct type for your machine.

- Thread Spool: The thread you want to wind onto the bobbin.

- Bobbin Winder: This is usually built into your sewing machine.

- Scissors or Thread Cutter: To snip the thread.

- Small Screwdriver (optional): Sometimes needed to adjust bobbin winder tension or if your bobbin case is tricky.

Understanding Different Sewing Bobbin Types

A critical first step is ensuring you have the right sewing bobbin types. Using the wrong bobbin can cause stitching problems, damage your machine, or both.

Common Bobbin Types

- Class 15 Bobbins: These are very common in many home sewing machines. They are typically plastic, slightly wider, and have a flatter edge.

- Class 15J Bobbins: Similar to Class 15 but often have a slight groove or notch for securing the thread tail.

- Class 66 Bobbins: Often found in older Singer machines. They are usually metal and have a rounded top.

- Class 100 Bobbins: Commonly used in Brother machines. They are usually clear plastic and have a specific shape.

- Metal Bobbins: Some machines, especially older or industrial ones, use metal bobbins. These are durable but can be noisier.

- Rotary Bobbins: Used in machines with a rotary hook system. These often have a distinct shape to fit the rotary hook mechanism.

How to Identify Your Bobbin Type:

The most reliable way to know your bobbin type is to check your sewing machine’s manual. If you don’t have the manual, look for markings on the bobbin itself or on the bobbin case. You can also take your existing bobbin to a sewing machine repair shop for identification.

Table: Common Bobbin Classes and Machine Brands

| Bobbin Class | Typical Machine Brands | Characteristics |

|---|---|---|

| Class 15 | Singer, Kenmore, Janome, White | Slightly wider, flatter edge, plastic or metal |

| Class 15J | Brother, Kenmore | Similar to Class 15, often with a thread groove |

| Class 66 | Older Singer models | Rounded top, often metal |

| Class 100 | Brother | Clear plastic, specific shape |

Preparing Your Sewing Machine for Bobbin Winding

Before you start how to thread a bobbin, you need to prepare your machine. This involves a few key steps to ensure smooth operation.

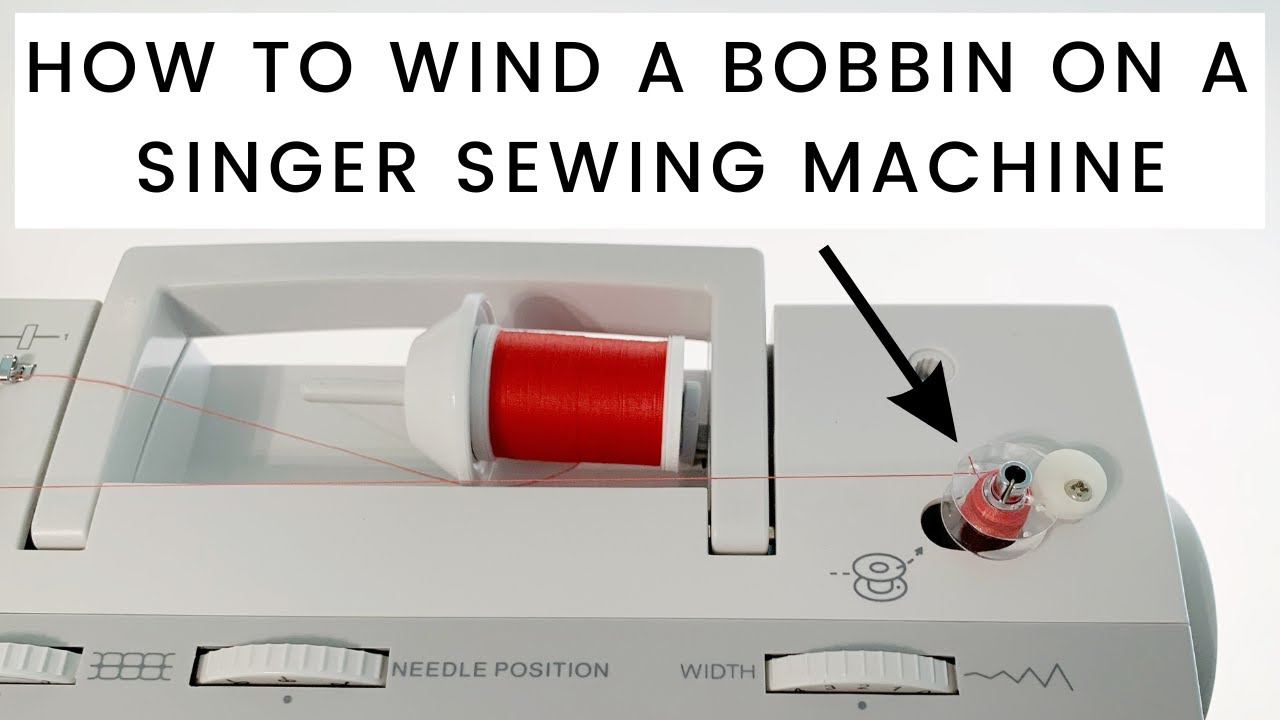

Step 1: Locate the Bobbin Winder

The sewing machine bobbin winder is typically a small spindle or post located on the top or side of your sewing machine. It’s often near where the thread spool sits.

Step 2: Place the Thread Spool

Put your thread spool on the spool pin. Ensure it’s facing the correct direction for your machine (check your manual if unsure – usually, the thread unwinds from the front). A spool cap might be needed to keep the spool from wobbling.

Step 3: Thread the Bobbin Winder Thread Guide

This is a crucial step for proper winding.

- Bring the thread from the spool to the bobbin winder thread guide. This is a small hook or hole designed specifically for winding the bobbin.

- Pass the thread through this guide.

- Continue the thread from the guide to the bobbin.

Step 4: Secure the Thread on the Bobbin

This prevents the thread from unraveling as you begin winding.

- Take the end of the thread and pass it through one of the holes in your bobbin.

- Pull a few inches of thread through the hole.

- Hold the bobbin and the thread end firmly against the bobbin.

Step 5: Place the Bobbin on the Bobbin Winder Spindle

Most machines have a separate spindle for winding bobbins.

- Slide the bobbin onto this spindle.

- Push the bobbin winder mechanism towards the machine’s flywheel (this engages the bobbin winder motor). Some machines have a lever, while others require you to slide the spindle. Check your manual!

Step 6: Cut the Thread from the Main Spool

Once the thread is secured through the bobbin hole and you’ve pulled a few inches through, cut the thread coming from the main spool, leaving a tail that’s still attached to the bobbin. This tail is what you’ll start winding with.

The Art of Winding a Bobbin: Step-by-Step Guide

Now, let’s get to the core of how to refill bobbin sewing machine. Follow these steps carefully for the best way to fill a bobbin.

Step 1: Engage the Bobbin Winder

Make sure your sewing machine is plugged in and turned on. You’ll need to engage the bobbin winder. As mentioned earlier, this usually involves pushing the bobbin winder spindle to the right or left to connect it to the motor. Your sewing machine needle should lift out of the way (your machine usually does this automatically when you engage the winder).

Step 2: Begin Winding

Gently press the foot pedal. The bobbin should start to wind. Hold onto the thread tail for the first few revolutions to ensure it’s secure and doesn’t slip.

Step 3: Guide the Thread

As the bobbin winds, use your fingers to guide the thread evenly across the bobbin. This is crucial for achieving good bobbin winding tension and preventing uneven winding, which can lead to skipped stitches or thread breaks. Move your fingers back and forth to distribute the thread smoothly.

Step 4: Cutting the Thread to Start

Once you’ve wound a few layers of thread around the bobbin and secured the tail, you’ll need to cut the thread.

- Stop the machine briefly.

- Use scissors or your machine’s thread cutter to cut the thread that is coming from the main spool.

- Continue winding a bobbin with the thread now solely coming from the spool to the bobbin. This ensures a clean start.

Step 5: Continue Winding and Monitoring

Keep your foot on the pedal, guiding the thread until the bobbin is nearly full. Most modern sewing machines have an automatic stop feature that will halt the winder when the bobbin is full. Older machines might not have this, so you’ll need to watch it carefully.

Tips for Even Winding:

- Consistent Speed: Try to maintain a steady speed with your foot pedal.

- Guide the Thread: Don’t rely solely on the machine; your fingers are your best tool for even distribution.

- Don’t Overfill: Overfilling can cause thread to snag or unravel. Stop winding when the bobbin looks full, but not overflowing.

Step 6: Disengage the Bobbin Winder

Once the bobbin is wound or the automatic stop engages, disengage the bobbin winder. This usually means pushing the spindle back to its original position. Remove the wound bobbin from the spindle.

Step 7: Trim the Thread Tail

Cut the remaining thread tail from the bobbin. Some bobbins have a small notch to help you secure the thread tail to prevent it from unwinding during storage.

Placing the Bobbin: Crucial for Stitch Quality

Now that you have a perfectly wound bobbin, the next step in how to refill bobbin sewing machine is correct bobbin placement. This is done within the bobbin case and is vital for proper stitch formation.

Step 1: Identify Your Bobbin Case Location

The bobbin case is where the bobbin resides during sewing. Its location varies by machine type:

- Top-Loading Bobbin: The bobbin case is usually visible on the sewing surface, under a clear plastic cover. The bobbin drops into a housing.

- Front-Loading Bobbin: The bobbin case is typically located in a compartment beneath a removable plate at the front of the machine, below the needle.

Step 2: Remove the Bobbin Case (If Necessary)

For front-loading machines, you’ll usually need to remove the bobbin case from its housing to insert the bobbin. For top-loading machines, the bobbin is inserted directly into the housing.

Step 3: Insert the Wound Bobbin

This is where thread direction matters!

- Check the Thread Direction: Hold the wound bobbin with the thread unwinding counter-clockwise (this is the most common direction for top-loading machines, but always check your manual). For front-loading machines, the direction might be clockwise.

- Place the Bobbin: Drop or slide the bobbin into the bobbin case or housing.

- Thread the Bobbin Case:

- For Top-Loading: After placing the bobbin, take the thread tail and pass it through the small slit in the bobbin case, then under the tension spring. Pull a few inches of thread through.

- For Front-Loading: After inserting the bobbin into the case, pull the thread tail through the slot in the case.

- Secure the Thread: Leave a tail of about 4-6 inches hanging from the bobbin case.

Step 4: Reinsert the Bobbin Case (If Applicable)

If you removed the bobbin case from a front-loading machine, carefully reinsert it into its housing. Ensure it clicks or seats correctly.

Step 5: Thread the Sewing Machine

Now you’re ready to thread the rest of your sewing machine, bringing the needle thread down to meet the bobbin thread.

- Pull the thread tail from the bobbin up through the bobbin area. You can do this by holding the needle thread and turning the machine’s handwheel towards you. The needle will catch the bobbin thread and pull it up.

- You should now have both the needle thread and the bobbin thread hanging out from under the presser foot.

Troubleshooting Common Bobbin Winding Issues

Even with the best intentions, you might encounter problems. Here are common issues and their solutions when winding a bobbin:

Issue 1: Uneven Winding

- Problem: Thread is wound loosely in some spots and tightly in others, or it’s piling up on one side.

- Causes:

- Not guiding the thread with your fingers.

- Winding at inconsistent speeds.

- Thread spool wobbling.

- Thread snagging on the spool or thread guide.

- Solutions:

- Always guide the thread with your fingers.

- Maintain a steady foot pedal speed.

- Use a spool cap or net if your spool is unstable.

- Check that the thread is moving freely from the spool.

Issue 2: Bobbin Not Winding at All

- Problem: The bobbin isn’t turning when you press the foot pedal.

- Causes:

- Bobbin winder is not engaged properly.

- Bobbin is on the spindle incorrectly.

- Machine is in “sewing” mode, not “bobbin winding” mode.

- Solutions:

- Ensure the bobbin winder spindle is fully pushed to engage.

- Make sure the bobbin is seated correctly on the spindle.

- Double-check that you’ve disengaged the needle bar if your machine requires it.

Issue 3: Thread Snapping During Winding

- Problem: The thread breaks while winding onto the bobbin.

- Causes:

- Sharp edges on the bobbin or bobbin winder.

- Thread is old or weakened.

- Winding too tightly.

- Incorrect bobbin winding tension setting (if adjustable).

- Solutions:

- Inspect your bobbins for damage.

- Try a new spool of thread.

- Avoid overfilling the bobbin.

- Check if your machine has a bobbin winder tension adjustment and try loosening it slightly.

Issue 4: Bobbin Stops Winding Prematurely

- Problem: The bobbin stops winding before it’s full.

- Causes:

- Automatic stop mechanism is faulty.

- Thread got caught somewhere.

- Solutions:

- Manually stop the machine and check for any thread snags.

- If the problem persists, consult your sewing machine manual or a technician.

Maintaining Your Sewing Machine for Optimal Bobbin Winding

Proper sewing machine maintenance plays a significant role in the ease and efficiency of bobbin winding.

Regular Cleaning

Dust and lint can accumulate in the bobbin area and the bobbin winder mechanism. Clean these areas regularly with a small brush or compressed air.

Lubrication

Refer to your sewing machine manual for lubrication points. A well-lubricated machine runs more smoothly, which includes the bobbin winder.

Needle Replacement

A dull or bent needle can cause thread to snag, leading to problems during bobbin winding. Replace your needle regularly, especially if you notice skipped stitches or thread breakage.

Checking the Bobbin Winder Tension

Some machines allow you to adjust the tension of the bobbin winder itself. If your thread is winding too loosely or too tightly, consult your manual for instructions on how to adjust this setting. Incorrect bobbin winding tension is a common culprit for poor stitching.

Frequently Asked Questions About Bobbin Winding

Here are some common questions sewers have about refilling bobbins:

Q1: Can I wind different types of thread on my bobbin?

A1: Yes, you can wind various types of thread, but it’s crucial to use the same type of thread for both your needle and bobbin for most sewing projects. Specialty threads might require specific bobbin winding techniques or machine settings. Always ensure your bobbin thread matches your top thread in terms of fiber content and weight for the best results.

Q2: How full should I fill the bobbin?

A2: Fill the bobbin until it’s nearly full, but not overflowing. Most machines have an automatic stop. If yours doesn’t, stop winding when the thread reaches the edge of the bobbin’s spool or just before it starts to build up unevenly on the sides. Overfilling can cause problems with thread feeding.

Q3: My bobbin thread is always breaking. What’s wrong?

A3: This can be caused by several factors: the bobbin thread is wound too tightly, the bobbin itself is damaged, the thread is old, or there’s lint in the bobbin area or tension discs. Ensure you’re using the correct sewing machine maintenance practices, and check for any burrs or rough spots on your bobbins and bobbin case.

Q4: What is the bobbin winding tension?

A4: Bobbin winding tension refers to how tightly the thread is wound onto the bobbin. Ideally, it should be wound evenly and smoothly, not too loose and not too tight. Some machines have an adjustable bobbin winder tension mechanism. If yours does, and you’re experiencing issues, you might need to fine-tune it according to your manual.

Q5: My bobbin spins freely but doesn’t seem to catch the needle thread.

A5: This usually indicates an issue with bobbin placement or how the bobbin case is threaded. Ensure the bobbin is seated correctly, the thread is pulled through the tension spring correctly, and that the needle thread is properly threaded through all the machine’s guides and tension discs before starting to sew.

Q6: Can I use a different brand of bobbin than the one that came with my machine?

A6: It’s best to use bobbins specifically recommended for your sewing machine model. While some bobbins are interchangeable across brands (e.g., Class 15), using an incorrect size or shape can cause significant stitching problems and even damage your machine’s hook mechanism. Always check your manual or consult with a dealer.

By following these detailed steps and tips, you’ll master the process of how to refill bobbin sewing machine. A well-wound bobbin is the foundation for beautiful, consistent stitches, making your sewing projects a joy to create!