Image Source: scalablepress.com

Learn How Much To Charge For Embroidery & Be Profitable

You want to know how much to charge for your embroidery work. This is a big question for anyone running this kind of business. It’s not a simple answer like one price for everyone. The right price depends on many things. Knowing these things helps you make money. It helps your business do well. This guide will show you how to figure out your prices.

Why Figuring Out Prices Matters

Setting your prices is very important. If prices are too low, you lose money. You work hard but don’t make enough to cover your costs. If prices are too high, no one will buy from you. You need to find the sweet spot. This spot covers your costs and gives you a profit. It also feels fair to your customers.

Good pricing means your business can grow. You can pay your bills. You can buy new things for your shop. You can pay yourself. It makes your business strong. This part of running your business is key. Don’t guess your prices. Figure them out with a plan.

What Goes Into The Price?

Many things make up the final cost of an embroidered item. Think of it like baking a cake. You need flour, sugar, eggs, and more. The cost of these things adds up. For embroidery, you have different parts that add up. These parts are the building blocks of your price.

These parts include:

- Materials you use

- The work you do

- Your business costs

- Setting up the design

- How complex the design is

- How many items are ordered

- How fast the customer needs it

We will look at each part. This helps you see why prices change. It helps you create your own embroidery pricing guide.

Adding Up Material Costs

Materials are the first part of your cost. You use thread. You use backing or stabilizer. You might use special needles. You also use the item you are embroidering on. This could be a shirt, hat, jacket, or bag.

- Thread: Good thread costs money. Different types of thread cost different amounts. Metallic thread costs more than rayon or polyester thread. The design size uses different amounts of thread. A small logo uses little thread. A large, dense design uses a lot.

- Backing/Stabilizer: This material goes behind the fabric. It keeps the stitches looking good. It stops the fabric from getting wrinkled or puckered. There are different types for different fabrics. Tear-away, cut-away, and wash-away are common types. You use a piece for each item. The cost per piece is usually low, but it adds up.

- Needles: Needles can break. They also get dull over time. You need to change them to get good results. This is a small cost, but it is a cost.

- The Item Itself: This is often the biggest material cost. A basic t-shirt costs less than a fancy jacket. The price you pay for the item is a big part of your cost. You need to know this exact cost.

Keep track of what these materials cost you. This is your starting point.

Figuring Out Your Embroidery Labor Cost

Your time is worth money. This is called labor cost. How long does it take you to do the work? This includes more than just the machine running.

Your labor includes:

- Getting the item ready (hooping)

- Setting up the machine

- Watching the machine while it sews

- Taking the item off the machine

- Trimming threads

- Checking the quality

- Packaging the item

How do you put a price on your time? Think about how much you want to earn per hour. Or think about how much you would pay someone else to do this work.

Let’s say you want to earn $20 an hour. If a job takes you 30 minutes of active work, your labor cost for that job is $10.

Sometimes, the machine runs for a long time by itself. But you are still there. You are still ready to fix problems. You are still using your knowledge. Count the time you are actively working on the order. Also, count the time the machine is running and you are supervising.

This embroidery labor cost needs to be covered in your price.

Covering Embroidery Business Overhead Costs

Running a business costs money even when you are not doing a specific job. These are overhead costs. They are like the bills you pay just to keep the doors open.

Think about these costs:

- Rent for your workspace (if you have one)

- Electricity and other utilities

- Internet and phone bills

- Machine maintenance and repairs

- Software costs (for digitizing, maybe)

- Insurance for your business

- Website costs

- Marketing and advertising

- Supplies like tape, scissors, markers

- Your own salary (if you pay yourself)

How do you add these to each job? First, add up all your overhead costs for one month. Let’s say it’s $1000.

Then, figure out how many hours you work on average in a month doing embroidery jobs. Let’s say you work 100 hours on jobs.

Your overhead cost per hour is $1000 / 100 hours = $10 per hour.

Now, for each job, estimate how long it takes you (labor + machine time). Add this hourly overhead cost to the labor cost for that job.

Example: A job takes 30 minutes (0.5 hours).

Labor cost (at $20/hour) = $10

Overhead cost (at $10/hour) = $5

Total labor + overhead for this job = $15

This helps you figure out what it truly costs you just to do the work, before materials and profit.

The Cost of Setting Up (Digitizing)

Before you can embroider a logo or design, you need a special file. This file tells the embroidery machine exactly where to put each stitch. Creating this file is called digitizing.

Digitizing is a skill. It takes time and special software. It’s a one-time cost for a specific design.

- If you digitize yourself: Your cost is your time and the software you bought. Figure out how long it takes you and use your hourly labor rate.

- If you pay someone else: They will charge you a fee. This fee depends on the complexity of the design. Simple text costs less than a detailed picture.

Digitizing fees can range from $25 for simple text to $100 or more for complex logos.

You need to decide how to charge for this.

- Charge a one-time setup fee: Customer pays the digitizing cost the first time they order that design. Future orders use the same file, so no fee. This is common for logo embroidery pricing chart setups.

- Include digitizing in the price per piece: Spread the digitizing cost across all the items in the first order. If digitizing is $50 and they order 10 shirts, add $5 per shirt. If they order 50 shirts, add $1 per shirt. This makes the per-piece price higher on small orders.

Most businesses charge a setup fee. It’s clear and covers the initial work.

Deciphering Stitch Count

Stitch count is a key factor in how much to charge for embroidery. The more stitches a design has, the longer it takes the machine to sew. More stitches also use more thread and put more wear on the machine.

A design with 5,000 stitches is much faster than one with 50,000 stitches.

Many people calculate embroidery price per stitch. This is a common way to price, especially for larger designs.

A basic price per stitch might be $0.001 to $0.005 per stitch. This number covers machine time, thread, and needle wear.

Example:

* Design A: 5,000 stitches at $0.003 per stitch = $15.00

* Design B: 50,000 stitches at $0.003 per stitch = $150.00

This method works well for designs of different sizes and densities. But it’s not the only way.

You can also use stitch count to estimate machine run time. If your machine sews 1000 stitches per minute, a 10,000 stitch design takes 10 minutes of machine time. You can then add a cost based on machine time.

Most embroidery software tells you the stitch count. This makes using this method easy.

Factoring in Design Complexity

Beyond stitch count, the design itself affects the work.

- Number of colors: Each color change takes time. The machine stops, you trim threads, and the machine starts again. Designs with many color changes take longer than designs with one or two colors, even with the same stitch count.

- Design density: Is the design open and airy? Or is it solid with stitches packed tightly together? Dense designs use more thread and can be harder to sew cleanly. They often need more underlay stitches too.

- Small details: Very small text or fine lines can be tricky to embroider well. They might require slower machine speeds or more careful hooping.

- Placement: Embroidering on a flat shirt front is easy. Embroidering on a hat, a small pocket, or a tricky spot like a sleeve cuff takes more skill and time to hoop correctly. This adds to your labor cost.

These custom embroidery cost factors mean that two designs with the same stitch count might not cost the same to produce. Your embroidery pricing guide should account for this. You might add a small extra fee for designs with many colors or difficult placements.

The Impact of Order Quantity

How many items is the customer ordering? This makes a big difference in pricing.

Think about the setup time:

* Getting the design ready on the machine

* Hooping the first item

* Starting the machine

This setup time happens whether you sew 1 item or 100 items. If you only sew 1 item, all that setup time cost goes onto that one item. If you sew 100 items, the setup cost is spread out. Each item costs less for setup.

Also, buying blank items in bulk is cheaper. You pay less per shirt if you buy 100 than if you buy 1. You should pass some of these savings to your customer.

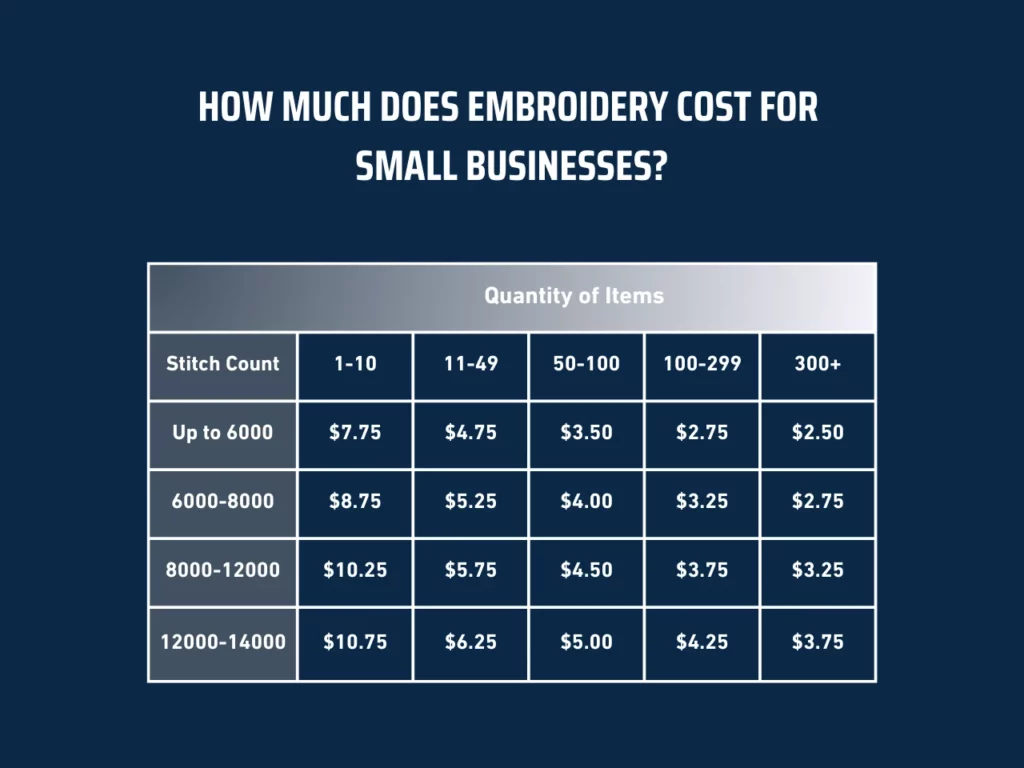

This is why there are often price breaks for larger orders. An embroidery pricing chart often shows lower prices per piece as the quantity goes up.

Example Pricing Tier (Simple):

| Quantity | Price Per Piece |

|---|---|

| 1-11 | $15.00 |

| 12-24 | $12.00 |

| 25-49 | $10.00 |

| 50+ | $8.00 |

This is just an example. Your prices will depend on all your costs.

Offering price breaks encourages customers to order more. It also reflects the lower cost per item for you on larger runs.

Considering Turnaround Time

How quickly does the customer need the order? Standard turnaround time might be 1-2 weeks. If someone needs 50 shirts tomorrow, that’s a rush order.

Rush orders often mean:

- You have to stop working on other jobs.

- You might have to pay extra to get the blank items quickly.

- You might have to work extra hours.

You should charge more for rush jobs. A common practice is to add a percentage fee for rush orders. Maybe an extra 25% or 50% of the total price.

Make sure your standard turnaround time is clear. List any extra fees for needing items faster. This is part of setting rates for embroidery services.

Calculate Embroidery Price Per Stitch (Detailed)

Let’s look closer at how to calculate embroidery price per stitch. This method is good for logos and designs where the stitch count varies a lot.

It involves figuring out a base price per stitch. This price needs to cover:

- Machine time cost

- Thread cost

- Needle/supply wear cost

How to find your machine time cost per stitch:

* Know your machine’s average speed (stitches per minute, SPM). Let’s say 800 SPM.

* Know your hourly cost for machine time (this is part of your overhead + some labor for supervision). Let’s say $15 per hour.

* $15 per hour / 60 minutes = $0.25 per minute.

* $0.25 per minute / 800 stitches per minute = $0.0003125 per stitch. This is your machine time cost per stitch.

How to find your thread cost per stitch:

* A large cone of thread might be $6 and have 5000 meters.

* 1 meter has about 600 stitches (this varies).

* Total stitches per cone: 5000 meters * 600 stitches/meter = 3,000,000 stitches.

* Cost per stitch for thread: $6 / 3,000,000 stitches = $0.000002 per stitch (very small!).

* Note: This is a rough estimate. Dense designs use more thread per stitch area. A simpler way might be to estimate thread cost is roughly related to stitch count and include it in the per-stitch price.

How to find other supply costs per stitch (needles, small things):

* Add up your monthly cost for needles, oil, cleaning supplies. Let’s say $50.

* Estimate total stitches sewn in a month. If you average 10 jobs at 20k stitches each per day, 20 days a month: 10 * 20,000 * 20 = 4,000,000 stitches.

* Cost per stitch for supplies: $50 / 4,000,000 stitches = $0.0000125 per stitch.

Total cost per stitch (example): $0.0003125 (machine) + $0.000002 (thread) + $0.0000125 (supplies) = $0.000327 per stitch.

This is your cost per stitch. You need to add your profit margin to this.

If you want a 50% profit margin on this part, you’d multiply the cost by 2 (or cost / (1 – profit margin percentage)).

Price per stitch = $0.000327 / (1 – 0.50) = $0.000654 per stitch.

Let’s round this up for ease, maybe to $0.001 per stitch as a base.

This base price per stitch ($0.001 in this example) can be used for part of your pricing. You still need to add:

* Cost of the blank item

* Your labor cost (hooping, trimming, packing)

* Your overhead cost (that isn’t covered in the machine time calculation)

* Digitizing fee (if applicable)

* Profit margin on all these costs

So, a job with 10,000 stitches on a $10 shirt, taking 15 mins labor (at $20/hr + $10/hr overhead = $30/hr cost), and $50 digitizing fee for 1 item:

- Stitch cost: 10,000 * $0.001 = $10.00

- Item cost: $10.00

- Labor/Overhead cost: 0.25 hours * $30/hour = $7.50

- Digitizing fee: $50.00

- Total Cost = $10.00 + $10.00 + $7.50 + $50.00 = $77.50

Now add profit. If you want a 40% profit on the total:

Price = Total Cost / (1 – Profit Margin Percentage)

Price = $77.50 / (1 – 0.40) = $77.50 / 0.60 = $129.17 for that one item.

This shows how calculating price per stitch is just one part of figuring out the total price. It helps price the “sewing” part.

How to Price Machine Embroidery: Different Methods

There are a few main ways businesses set rates for embroidery services.

- Price Per Stitch: As discussed, you calculate a rate per stitch and multiply it by the stitch count. You still add the item cost, labor, overhead, and digitizing. This works well for varying design sizes.

- Price Per Piece (Flat Rate based on size/location): You set flat prices based on the size of the design and where it goes on the item.

- Small left chest logo (under 10k stitches): $X per piece

- Medium back design (10k-25k stitches): $Y per piece

- Large back design (25k+ stitches): $Z per piece

This is simpler for customers and fast for you to quote. You base these flat rates on your average stitch counts for those sizes and locations, making sure they cover costs and profit.

- Price Based on Machine Time: You figure out your hourly cost for using the machine (covering machine overhead, wear, and supervision labor). You track or estimate how long each job takes on the machine. Multiply time by your hourly rate. Add material costs, other labor, and digitizing. This is accurate but requires good time tracking.

- Value-Based Pricing: You price based on what the customer feels the item is worth, not just your costs. If you do high-quality work on premium items for a niche market, you might charge more than someone doing basic logos on cheap shirts. This requires knowing your market and your unique value.

Most businesses use a mix. They might have a logo embroidery pricing chart based on quantity and standard logo size (a per-piece approach). For larger or custom designs, they might switch to a per-stitch calculation or a quote based on complexity and estimated time.

A simple way to start is using the per-piece method for common jobs and a per-stitch method for others. Always make sure all your costs (materials, labor, overhead, digitizing) are covered, plus your desired profit margin.

Building Your Embroidery Pricing Guide

Now you have the pieces. How do you put them together into a clear guide for yourself and your customers?

Your guide should:

- List standard items you embroider (shirts, hats, etc.) and their base costs.

- Explain how design size or stitch count affects the price (e.g., small logo vs. large logo).

- Show price breaks for quantity.

- Mention the digitizing or setup fee. Explain if it’s one-time.

- Note extra costs for complexity (many colors, tricky placement) or rush orders.

- State your standard turnaround time.

Example Table Snippet (part of a guide):

| Item | Base Price (Blank Item + Basic Labor/Overhead) | Left Chest Logo (up to 8000 stitches) Price Add | Full Back Design (up to 25000 stitches) Price Add |

|---|---|---|---|

| Basic T-Shirt | $12.00 | +$8.00 | +$25.00 |

| Polo Shirt | $18.00 | +$8.00 | +$25.00 |

| Baseball Cap | $10.00 | +$7.00 (Front) | N/A |

Note: This table is simplified. Your real guide needs more detail.

Your full embroidery pricing guide will show customers quickly what to expect. It helps you give fast quotes.

For custom designs or items not on your list, you’ll use the factors we discussed (stitch count, complexity, time) to create a specific quote.

Average Cost of Embroidery Per Piece

Customers often ask, “What is the average cost of embroidery per piece?” This is hard to answer generally because, as we’ve seen, it depends a lot on the details.

However, we can give a rough idea for common jobs.

- Small logo (e.g., left chest) on a polo shirt: This is a very common request. The blank shirt might cost $15-$25. The embroidery might add $6-$15 per piece, depending on stitch count, quantity, and the business’s pricing. So, a final price could be $21 to $40+ per shirt.

- Logo on a hat: A common price might be $8-$15 for the hat itself, plus $6-$12 for the embroidery. Total: $14 to $27+ per hat.

- Large back design on a jacket: Jackets are more expensive ($25 – $100+). A large back design could add $20-$60+ for the embroidery part alone, based on stitch count. Total price varies greatly.

These are just averages. Your prices might be higher or lower based on your costs, your quality, and your market.

It’s helpful to know these averages to see if your potential prices are in the right ballpark. But don’t set your prices based only on what others charge. You must cover your costs.

Setting Rates For Embroidery Services

Setting rates for embroidery services is about combining everything we’ve talked about. You need a system.

Here’s a simple process:

- Calculate Your Costs:

- Figure out your hourly labor cost.

- Figure out your hourly overhead cost.

- Figure out your cost per stitch (or cost per minute of machine time).

- Know the cost of blank items.

- Know your digitizing costs (if applicable).

- Choose Your Pricing Method: Will you use per stitch, per piece, or a mix?

- Determine Desired Profit Margin: How much money do you want to make on top of your costs? This might be a percentage (e.g., 40% or 50%). Profit margin is key to a healthy business.

- Price = (Total Costs + Desired Profit Amount) OR

- Price = Total Costs / (1 – Desired Profit Percentage)

- Create Your Pricing Tiers: Set up quantity discounts.

- Add Fees: Decide on setup fees, rush fees, and fees for complex work.

- Write Your Guide: Put all this information into a clear embroidery pricing guide or chart.

Let’s try an example: Pricing 24 polo shirts with a 7000-stitch logo.

- Blank Item Cost: Polo shirt costs you $15.00 each. For 24 shirts: $15.00 * 24 = $360.00

- Digitizing: Assume logo is new. $50 setup fee. (Customer pays this, or you build it in). Let’s add it as a one-time fee.

- Embroidery Cost Per Piece: Using a per-stitch method. Let’s say your price per stitch covers machine time, thread, and machine overhead at $0.0012 per stitch.

- 7000 stitches * $0.0012/stitch = $8.40 per shirt for the sewing part.

- Labor/Overhead Cost (not covered by stitch rate): Hooping, trimming, packing time. Estimate 5 minutes per shirt. Your combined labor/overhead cost is $30/hour ($0.50 per minute).

- 5 minutes * $0.50/minute = $2.50 per shirt for this handling time.

- Total Cost Per Shirt (excluding digitizing): $15.00 (item) + $8.40 (sewing) + $2.50 (handling) = $25.90 per shirt.

- Desired Profit Margin: Let’s aim for a 45% profit margin on the cost per piece.

- Price per shirt (before digitizing) = $25.90 / (1 – 0.45) = $25.90 / 0.55 = $47.09 per shirt.

- Total for 24 shirts: $47.09 * 24 = $1129.96

- Add Digitizing Fee: $1129.96 + $50 = $1179.96

- Final Quote: $1179.96 for 24 shirts with a 7000-stitch logo and one-time digitizing fee.

- Price Per Piece (for customer): $1179.96 / 24 shirts = $49.17 per shirt (this includes a share of the digitizing cost spread over 24 shirts). You could also quote $47.09 per shirt + a $50 setup fee.

This example shows how costs and profit build the price. Remember to check what the average cost of embroidery per piece is in your area for similar work. If your calculated price is very different, you might need to adjust your costs, your profit goal, or your process.

Ensuring Your Embroidery Profit Margin

Profit is not a dirty word. It’s necessary for your business to live and grow. Your embroidery profit margin is the money left over after you pay all your costs.

How to make sure you have a good profit margin:

- Know ALL Your Costs: Don’t forget anything – thread, needles, electricity, software, your time, everything! Underestimating costs is a fast way to kill your profit.

- Set a Profit Goal: Decide what percentage profit you need on each job or overall. This goal should allow you to reinvest in your business, handle slow times, and pay yourself a fair wage. A common goal is 40-60% margin on the decorated part (not including the blank item cost). Or a lower percentage (like 20-30%) on the total price including the item.

- Price Correctly: Use the methods above to calculate prices that cover costs PLUS your profit goal. Don’t just match the lowest price you see online.

- Be Efficient: The faster and better you work, the lower your labor and machine time costs per piece. This increases your profit margin without raising prices.

- Manage Materials: Don’t waste thread or backing. Buy materials smartly.

- Track Everything: Keep records of your costs, your time on jobs, and your sales. This helps you see if you are making the profit you planned.

Regularly review your pricing. Are your costs going up? Are you working faster? Do your prices need to change?

Setting rates for embroidery services should always start with knowing your costs and what profit you need.

Logo Embroidery Pricing Chart Example

Here is a basic example of a logo embroidery pricing chart. This is common for businesses focusing on corporate or team apparel. It assumes a standard logo size (e.g., up to 10,000 stitches) and does not include the cost of the blank item or digitizing fee in this table. These would be added on top.

Embroidery Price Per Piece (Logo up to 10,000 stitches)

| Quantity | Price Per Piece (Embroidery Only) |

|---|---|

| 1-11 | $12.00 |

| 12-24 | $9.00 |

| 25-49 | $7.50 |

| 50-99 | $6.00 |

| 100-249 | $5.00 |

| 250+ | Contact for Quote |

Other Potential Fees:

- Digitizing Fee: $50 (one-time fee per logo)

- Names/Numbers: Add $5-$10 per item (for individual names or numbers)

- Rush Fee: Add 25% for delivery in under [Your standard time, e.g., 5 business days]

This kind of logo embroidery pricing chart is clear for customers. They can quickly see the embroidery cost based on how many items they need. Remember, you still need to add the cost of the actual shirt, hat, etc., and the digitizing fee (if it’s a new logo).

When you create your own chart, make sure the prices per piece in each tier cover your material use (thread, backing per item), labor per item, a portion of your overhead per item, and your desired profit margin. The price goes down per item as quantity increases because your fixed costs (like machine setup time for the run) are spread over more items, and your material cost per item might decrease with bulk buying.

Custom Embroidery Cost Factors Recap

Let’s quickly review the main things that change the price for custom embroidery:

- Item Type: A jacket costs more than a t-shirt. Hard-to-hoop items cost more labor.

- Design Size & Stitch Count: More stitches = more time and thread = higher cost. This is why ‘calculate embroidery price per stitch’ is useful.

- Design Complexity: Many colors, fine details, high density, tricky placement = more labor/time = higher cost. These are key custom embroidery cost factors.

- Quantity: More items = lower price per item.

- Digitizing: New designs need a setup file, which costs money (one time).

- Turnaround Time: Needing it fast usually costs extra.

When a customer asks for a quote, go through these points. Ask questions to get the details you need to give an accurate price.

Putting It All Together: Your Pricing Strategy

You have learned about the different costs and ways to price. Now, build your own strategy.

- Know Your Numbers: Add up your monthly overhead. Track your time. Calculate your cost per stitch or machine minute. Know your item costs. This is the base of your embroidery pricing guide.

- Define Your Standard Services: What are the typical jobs you do? (e.g., left chest logos on polos, hat fronts). Set standard pricing for these based on quantity using a method like the per-piece chart.

- Develop a Method for Custom Quotes: For jobs that don’t fit your standard services (large designs, special items), use a method based on stitch count, estimated machine time, or complexity to calculate the price.

- Decide on Fees: Be clear about digitizing fees, rush fees, and name/number costs.

- Add Your Profit: Make sure your prices include the profit margin you need.

- Write It Down: Create your internal pricing worksheet and an external embroidery pricing guide for customers.

- Review and Adjust: Check your pricing often. Are you making money? Are customers happy with the value? Are your costs changing? Change your prices when needed. Don’t be afraid to raise prices if your costs go up or you add more value.

Setting rates for embroidery services takes work. But doing it right means your business can be successful and profitable. You will know how much to charge for embroidery with confidence.

Frequently Asked Questions (FAQ)

Q: Should I charge by stitch count or per piece?

A: Many businesses use a mix. Charging per piece is simple for standard logos and quantities. Charging per stitch is good for larger, more complex designs where stitch count varies a lot. Use the method that works best for the job and is easiest for you and the customer. Just make sure either method covers all your costs plus profit.

Q: How much should I charge for a logo that is already digitized?

A: If the customer provides a usable embroidery file (like a .DST, .EXP, etc.), you should not charge them a digitizing fee again. You still charge for the embroidery itself (based on stitch count, quantity, etc.) and the blank item.

Q: How do I price names and numbers on shirts?

A: Names and numbers are usually priced as an extra fee per piece. They are often standard fonts, so there is no digitizing fee if you have the font file. Charge a flat rate per name or number, perhaps $5-$10 depending on the size and stitch count of the lettering, plus the labor to sew each one individually.

Q: What is a good profit margin for embroidery?

A: This varies greatly by business type and market. However, many successful embroidery businesses aim for a profit margin between 40% and 60% on the embroidery service itself (not including the blank item cost), or a total profit margin of 20-30% on the final price including the item. Calculate your costs first, then set a profit goal that allows your business to thrive.

Q: How do I handle small orders or single items?

A: Small orders are less profitable per piece because setup costs are spread over fewer items. You have a few options:

1. Charge a higher price per piece for low quantities (as shown in pricing tiers).

2. Have a minimum order amount (e.g., minimum $50 or 6 pieces).

3. Charge a specific “small order fee” in addition to the per-piece price for orders below a certain number. Be clear about your policy.

Q: How much should I charge for digitizing?

A: Digitizing fees depend on the complexity of the design. Simple text or basic shapes might be $20-$40. A complex logo with many colors and details could be $50-$150 or more. If you digitize yourself, charge based on your hourly rate and the time it takes. If you use a service, charge what they charge you, or add a small markup if you handle the process.

Remember, your pricing is a reflection of your quality, service, and business costs. Price correctly to be profitable and sustainable.