Image Source: i.ytimg.com

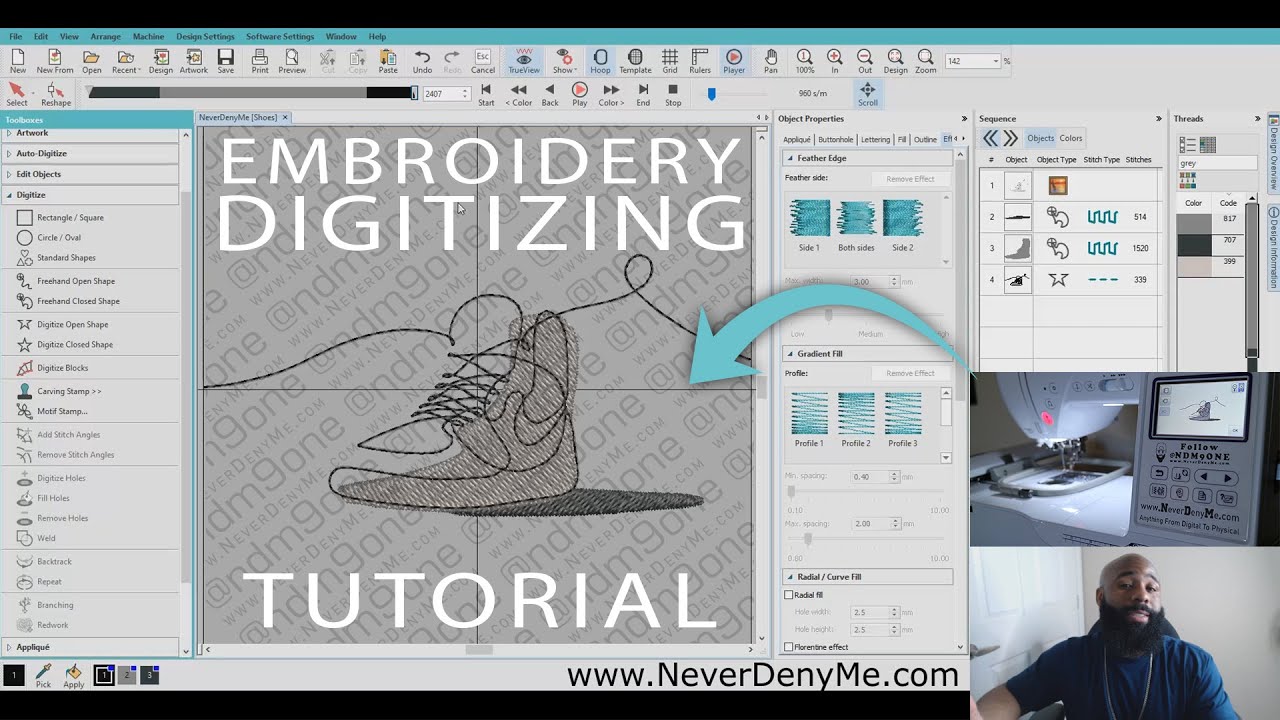

Learn How Do You Digitize Embroidery Designs Step-by-Step

Do you want to turn a picture into a stitch file? Can you make your own designs for machine embroidery? Yes, you can! Many people learn to do this themselves. Embroidery digitizing is the art of changing an image into a special file. This file tells an embroidery machine where to put each stitch. It is like telling a robot exactly what to sew. This skill is used by hobbyists, small businesses, and large factories. They all want to make unique and beautiful embroidered items. Let us look at how you can do this step-by-step.

Starting Your Digitizing Journey

Starting to digitize embroidery designs might seem hard. But with the right tools and steps, it becomes fun. You can create amazing stitch files from almost any image.

Picking Your Tools: The Software You Need

The very first thing you need is embroidery digitizing software. This special program lets you draw stitches on your computer. It turns your artwork into instructions for an embroidery machine.

There are many types of software:

* Free Software: Some programs are free. They are good for trying out digitizing. But they often have fewer features. They might not give you the best embroidery design quality.

* Paid Software: Most good software costs money. They offer many tools for detailed work. These include programs like Wilcom, Hatch, Embrilliance, and Brother PE-Design. These are often considered the best embroidery digitizing tools.

* Subscription Software: Some companies let you pay a small fee each month. This can be a good way to use expensive software without buying it all at once.

When you pick software, think about:

* Your Skill Level: Are you a beginner or do you know a lot about computers?

* Your Budget: How much money can you spend?

* Features You Need: Do you want to do simple letters or complex pictures?

Most software needs a good computer. A fast processor and enough memory help the program run smoothly.

Your Design Source: What Will You Digitize?

Next, you need something to digitize. This is your artwork. It could be:

* A drawing you made.

* A picture from the internet.

* A logo.

* A piece of clip art.

This is where converting images to embroidery starts. The quality of your starting image is very important. A clear, crisp image will be much easier to work with. A blurry or pixelated image will make your job harder. It can also lead to poor embroidery design quality.

The Step-by-Step Digitizing Process

Let us break down the embroidery design creation process. We will go through each step carefully.

Step 1: Choose Your Design and Software

First, pick the image you want to digitize. Keep it simple when you are starting out. A basic shape or a simple logo is best. This helps you learn the tools without getting lost.

Then, open your chosen embroidery digitizing software. You will load your image into the program. This image will be your guide. You will draw stitches on top of it.

Step 2: Prepare Your Artwork

Good digitizing starts with good artwork. This step is very important.

Why Clear Artwork Matters

Imagine trying to trace a blurry picture. It is hard, right? The same goes for digitizing. Your software needs a clear guide.

* Clean Up Your Image: Remove any extra lines or colors. Make sure the edges are sharp.

* Use High-Resolution Images: This means the image has many tiny dots (pixels). More dots mean a clearer picture.

* Consider Vector Art: This is a big help. Vector art for digitizing is like a perfect drawing. It uses math to create shapes. This means you can make it any size without it getting blurry. Regular pictures (raster images) get blurry when you make them big. Vector art always stays sharp.

* Raster Images (like JPEGs, PNGs): Made of tiny squares of color. Good for photos. Bad for resizing.

* Vector Art (like SVGs, AI, EPS): Made of points, lines, and curves. Good for logos and drawings. Stays clear at any size.

If you can, use vector art. If you only have a raster image, make sure it is high quality. Many digitizing programs have tools to help clean up raster images. Some can even try to turn raster into vector. This is not always perfect, but it helps.

Step 3: Define Stitch Types and Properties

This is where you tell the machine how to sew. You choose different stitch types for different parts of your design.

Exploring Stitch Types

- Fill Stitches (Tatami or Complex Fill): These stitches fill in large areas. Think of filling a big shape like a circle or a square. They lay down stitches side-by-side. You can change how close they are (density). This affects how thick or thin the embroidery looks.

- Satin Stitches: These are narrow, close stitches. They create a smooth, raised look. They are perfect for letters, outlines, or small shapes. Imagine sewing a shiny ribbon. That is a satin stitch.

- Run Stitches: These are simple lines of stitches. They are good for outlines, small details, or connecting parts of a design. There are different kinds:

- Single Run: A basic line.

- Triple Run: A bolder line, made of three stitches on top of each other. It looks thicker and more defined.

Adjusting Stitch Properties

- Density: This is how close your stitches are. High density means more stitches, a thicker look, but can make the fabric stiff. Low density means fewer stitches, a lighter look, but might show the fabric underneath. You need to find a good balance.

- Pull Compensation: Fabric stretches when you sew on it. This can make your design look smaller than it should. Pull compensation adds a tiny bit of width to your stitches. This fights the fabric pull. It makes your design end up the right size. This is a very important part of good embroidery design quality.

- Underlay: These are light stitches sewn first, hidden under the main stitches. They help stabilize the fabric. They also give the main stitches a good base to sit on. Imagine building a house; underlay is like the foundation. It makes the top stitches look smoother and stand out more.

Each part of your design will need different stitch types and settings. You learn these choices with practice.

Step 4: Digitize the Design: Manual vs. Auto Features

Now comes the actual drawing of stitches. You have two main ways to do this: manual embroidery digitizing or using auto digitizing features.

Manual Digitizing: Full Control

- What it is: You draw every single stitch path yourself. You click points on your screen to define outlines and fill areas. You tell the software exactly where each stitch should go.

- Why use it: This gives you the best control. You can make very precise designs. You can make sure stitches flow well and look good. This is how pros get the highest embroidery design quality.

- When to use it: For complex logos, detailed artwork, or when you need perfect results. It takes more time and skill.

Auto Digitizing Features: Quick and Easy (Sometimes)

- What it is: The software tries to digitize the image for you. You click a button, and it attempts to turn areas of color into stitches.

- Why use it: It is fast. It is easy for beginners.

- Limitations: Auto digitizing features are not perfect. They often make many mistakes. They might create too many stitches, stitches in the wrong direction, or strange overlaps. The design might not look good when sewn. You often need to clean up the auto-digitized file.

- When to use it: For very simple, basic shapes. Even then, you will likely need to fix things manually. For professional work, manual digitizing is always better.

For good results, even if you use auto-digitizing, you will spend time on manual embroidery digitizing to fix errors. This part of the embroidery design creation process is where your skill grows. You learn to “see” how the stitches should lay.

Step 5: Optimize and Edit

Once you have laid down your stitches, your work is not done. This is where you polish the design.

- Rearrange Elements: Maybe a part needs to sew before another. Change the stitch order so that colors are stitched logically. This minimizes color changes and machine stops.

- Change Colors: Assign thread colors to different parts of your design.

- Add Trims and Jumps:

- Trims: These tell the machine to cut the thread. You want trims between parts that are far apart. This avoids long, messy threads on the back of your embroidery.

- Jumps: These are movements where the needle is up. They are like taking a small step without sewing. You want to reduce unnecessary jumps.

- Fix Overlaps: Make sure different parts of the design do not overlap too much. This can make the embroidery too thick.

- Check Stitch Direction: Ensure stitches flow in a nice direction. For example, letters should have stitches that follow the shape of the letter. This makes the embroidery design quality much better.

This step is very important for the final look and for how smoothly your machine sews the design.

Step 6: Save and Export

Finally, you save your design. But you cannot just save it as a regular image file. Embroidery machines need special files.

Machine Embroidery File Formats

- Different Machines, Different Files: Every brand of embroidery machine uses its own file format. It is like how different phones use different chargers.

- DST (Tajima): A very common file type. Many machines can read it. It is like the “PDF” of embroidery files. It is also often the standard file for commercial machines.

- PES (Brother, Baby Lock, Bernina): Popular for home embroidery machines.

- JEF (Janome): Used by Janome machines.

- HUS (Husqvarna/Viking): Used by Husqvarna Viking machines.

- EXP (Melco): Another common commercial format.

- VP3 (Husqvarna/Viking, Pfaff): Newer format for some Husqvarna and Pfaff machines.

- XXX (Singer, Compucon): Used by Singer machines.

Your embroidery digitizing software will let you export your design into many of these machine embroidery file formats. Always save your design in your software’s native format first. This lets you go back and edit it easily later. Then, export it to the format your machine needs.

Key Elements of Quality Digitizing

Achieving high embroidery design quality goes beyond just tracing. It involves a deep grasping of how fabric and thread work together.

Mastering Stitch Types and Their Purpose

Let us look closer at why certain stitch types are chosen.

Fill Stitches (Tatami/Complex Fill)

- Purpose: To cover large areas evenly.

- Choices: You can change the angle of the stitches. This creates texture. You can also make them loose or dense. Too dense, and the design becomes stiff. Too loose, and the fabric shows through. Good digitizers choose the right density for the fabric.

Satin Stitches

- Purpose: To make raised, smooth lines. Great for text and borders.

- Choices: Satin stitches have a width limit. If they get too wide, they might not look good. They can snag. For wide areas, you might switch to a fill stitch or use special techniques to keep the satin looking nice.

Run Stitches (Single, Triple)

- Purpose: For thin lines, outlines, or quick details.

- Choices: Triple run stitches are used when you want a bolder line. Single run stitches are fine for light outlines or to connect small elements.

Specialty Stitches (e.g., Appliqué)

- Purpose: To add fabric pieces to your design.

- Choices: Digitizing for appliqué involves specific steps. You digitize a placement line, then a tack-down line, and finally a cover stitch. This is a special part of the embroidery design creation process.

Compensations and Underlays

These are vital for a good finish.

Push/Pull Compensation: Balancing Fabric Movement

- What it is: When a needle goes through fabric, it pulls the fabric inward a little. This can make sewn shapes smaller or narrower than intended. Push compensation adds a small amount to the width of the design. This makes sure the final sewn result is the correct size. Pull compensation is the opposite; it makes small areas slightly larger so they don’t get lost.

- Why it’s needed: Without it, circles might look like ovals, and squares might look like rectangles. Good compensation ensures the shape stays true.

Underlay Stitches: The Hidden Foundation

- What they are: Light stitches sewn underneath the main stitches. They are usually short and zig-zag.

- Why they are important:

- Stability: They hold the fabric flat. This stops the fabric from puckering or pulling.

- Loft: They give the top stitches something to sit on. This makes the main stitches look puffier and stand out more.

- Coverage: They help cover the fabric, especially for designs that need to be dense.

- Minimizing show-through: If your top stitches are not very dense, underlay can prevent the fabric from showing through.

Sequencing and Trims

The order in which your machine sews parts of a design is called sequencing.

- Stitch Order: Think about the layers. Usually, you sew smaller details or outlines on top of larger fill areas. You want to avoid sewing over already dense stitches too much. Plan your colors too. If two parts share a color, sew them one after the other to reduce thread changes.

- Minimizing Jump Stitches: Jumps are when the machine moves the needle without sewing. Long jumps create loose threads on the back of your embroidery. These threads often need to be trimmed by hand. Good digitizing minimizes these jumps. You can do this by planning your stitch path carefully. You can also use “connectors” – small, very short run stitches that connect parts of a design without a trim.

Digitizing for Different Fabrics

Fabric choice greatly impacts how you digitize.

- Thick Fabrics (like denim): Need longer stitches and more underlay to push through the material.

- Thin Fabrics (like silk): Need lighter density, less underlay, and gentler pull compensation to prevent puckering or damage.

- Stretchy Fabrics (like t-shirts): Need more underlay and careful use of pull compensation to prevent distortion. You might also use specific underlay types that run against the stretch.

- Piles (like towels): Need dense stitches or special underlay (like a knock-down stitch) to push down the nap so the design sits on top.

Good embroidery design quality comes from knowing how these elements work together.

Choosing the Right Tools: Software and Beyond

To digitize effectively, you need more than just a computer. Let us look at some best embroidery digitizing tools.

Popular Embroidery Digitizing Software

Here are some widely used programs, varying in features and price:

- Wilcom Hatch Embroidery:

- Good for: Beginners and experienced users.

- Features: User-friendly interface, powerful auto-digitizing features (though still need manual refinement), excellent stitch quality, many design tools.

- Cost: Mid-to-high range.

- Embrilliance StitchArtist:

- Good for: Modular design, letting you buy only the features you need. Works well on Mac and PC.

- Features: Different “levels” for different skill sets (Level 1 for basic, Level 3 for advanced), easy to learn, good for hobbyists.

- Cost: Varies by level.

- Brother PE-Design:

- Good for: Brother machine owners.

- Features: Made to work perfectly with Brother machines, offers good digitizing and editing tools, often bundled with machines.

- Cost: Mid-range.

- Wilcom Embroidery Studio:

- Good for: Professional digitizers, commercial use.

- Features: Industry standard, extremely powerful, every tool imaginable for high-volume production and complex designs, but has a steep learning curve.

- Cost: Very high.

- Tajima Pulse:

- Good for: Professional digitizers, especially for Tajima machines.

- Features: Another industry-standard software, robust tools, excellent for production.

- Cost: Very high.

When picking, think about how much you will use it and what your goals are. Many offer free trials. Try them out before you buy!

Other Essential Hardware

- Computer: A powerful computer makes a difference. Digitizing software can use a lot of memory and processing power.

- Mouse/Tablet: A good mouse or a graphics tablet can make drawing stitches easier and more precise, especially for manual embroidery digitizing.

- Large Monitor: More screen space helps you see your design details.

When to Digitize Yourself vs. Hiring a Service

So, should you learn to digitize, or should you pay someone else? This is a common question.

Doing It Yourself (DIY)

Pros:

* Full Control: You have total say over your design. You can make it exactly how you want.

* Save Money (Long Run): Once you own the software, you do not pay per design.

* Learn a Skill: It is rewarding to create your own designs.

* Quick Edits: You can make small changes quickly without waiting for someone else.

Cons:

* High Start-Up Cost: Software can be expensive.

* Time-Consuming: Learning takes time. Digitizing each design takes time.

* Steep Learning Curve: It can be hard at first. There is much to learn.

* Quality Issues: Your early designs might not have the best embroidery design quality.

Hiring a Digitizing Service

Pros:

* Professional Quality: Experts know how to make top-notch designs. This ensures the best embroidery design quality.

* Save Time: You just send your image and get back a ready-to-sew file.

* No Software Cost: You do not need to buy expensive programs.

* No Learning Curve: You do not need to learn the skill yourself.

Cons:

* Cost Per Design: Each design costs money. Digitizing service cost can add up if you have many designs.

* Less Control: You might not get exactly what you want on the first try. You depend on someone else.

* Waiting Time: You have to wait for the service to complete your order.

* No Skill Gained: You do not learn how to digitize yourself.

Understanding Digitizing Service Cost

The digitizing service cost varies a lot. It depends on:

* Complexity: A simple text logo costs less than a detailed picture.

* Size: Larger designs usually cost more.

* Stitch Count: Some services charge by the number of stitches.

* Rush Orders: Need it fast? You will pay more.

* Service Provider: Prices vary between different companies.

For someone just starting, hiring a service for complex designs can be a good idea. You can learn to digitize simpler things yourself.

Tips for Achieving Great Embroidery Design Quality

Here are some tips to make your designs sew out beautifully:

- Test Sew Every Design: This is the most important step! Always sew a sample of your digitized design on a similar fabric. The computer screen does not show how it will look on fabric. You will see any errors like:

- Gaps between colors.

- Too much puckering.

- Stitches that are too dense or too loose.

- Wrong stitch order.

- Review Stitch Paths: Before sewing, use your software’s “stitch simulator” or “slow redraw” feature. Watch how the machine will sew the design. Look for odd jumps, messy connections, or stitches going in strange directions.

- Keep it Simple for Beginners: Do not start with a super complex image. Master the basics of fills, satins, and runs first. Work on simple text or basic shapes.

- Learn from Mistakes: Every bad sew-out is a lesson. Figure out what went wrong. Did you forget pull compensation? Was the underlay wrong for the fabric?

- Join Online Groups: There are many online communities for embroidery digitizers. You can ask questions, share your work, and get advice.

- Watch Tutorials: Many people share free lessons online.

- Invest in Training: Some software companies offer paid classes. This can be a fast way to learn from experts.

- Good Artwork is Key: Remember our talk about vector art for digitizing and clear images? It makes digitizing so much easier and the end result better.

- Know Your Fabric: Always think about what you are sewing on. This changes how you digitize for density, underlay, and compensation.

Digitizing embroidery designs is a mix of art and technical skill. With patience and practice, you can create amazing stitch files that bring your designs to life.

Frequently Asked Questions (FAQ)

How long does it take to learn embroidery digitizing?

It varies a lot! For basic designs, you might learn the core steps in a few weeks or months. To become truly skilled and create complex designs with high embroidery design quality, it can take years of practice. It is a journey of continuous learning.

Can I use any image to digitize?

Yes, technically you can use almost any image. However, the easier answer is no. For good results, you need a high-quality, clear image. Blurry, pixelated, or very complex images with many tiny details are very hard to digitize well. Vector art is always best.

What’s the best software for beginners?

There is no single “best.” Many suggest Wilcom Hatch Embroidery or Embrilliance StitchArtist as good choices for beginners. They have user-friendly interfaces but also offer depth as you grow. Check for free trials to see what feels right to you. These are often listed among the best embroidery digitizing tools for home users.

Is free digitizing software good enough?

For simple, basic shapes or just to try out the process, free software can be a starting point. However, it often lacks the advanced tools, precise controls, and different stitch types needed for professional-looking embroidery design quality. For serious digitizing, paid software is usually a necessary investment.

Do I need an embroidery machine to learn digitizing?

No, you do not need an embroidery machine to learn digitizing. You can learn the software and create designs. However, it is highly recommended to have access to a machine to “test sew” your designs. This is the only way to truly see how your digitizing choices affect the final product. Test sewing helps you learn and improve your embroidery design quality greatly.