How much does embroidery cost? Well, it’s not just one price. The cost of machine embroidery changes a lot. It depends on many things. This embroidery pricing guide will help you learn about these factors. We will look at the embroidery service cost and what makes it go up or down.

Image Source: scalablepress.com

Deciphering What Affects Embroidery Prices

Many things play a part in the final price you pay for embroidery. Knowing these helps you guess the cost. It also helps you know what info to give when you ask for a price. Here are the main embroidery cost factors.

Grasping Stitch Count and Design Work

This is a big one. Embroidery machines work by making stitches. The more stitches a design needs, the longer the machine runs. Longer run time means more cost.

- Simple designs: Need fewer stitches. Cost less.

- Detailed designs: Need many stitches. Cost more.

- Solid fill areas: These areas are covered completely with stitches. They use a lot of stitches.

- Outline designs: Just sew the edge. Use fewer stitches. Cost less.

Many shops base their price partly on the embroidery cost per stitch. They figure out how many stitches are in your design. Then they multiply that number by a small price per stitch. So, more stitches always means a higher cost for the embroidery part.

How Many Colors Your Design Uses

Does your design have one color? Or ten colors? This matters.

- Each color needs a different spool of thread.

- The machine must stop and change threads for each new color.

- Stopping and starting takes time. Time costs money.

So, designs with many colors often cost a little more than designs with just one or two colors, even if the stitch count is the same.

The Size of the Design

This seems simple, right? A bigger design must cost more. And it usually does. Why?

- Bigger designs almost always need more stitches.

- More stitches mean the machine runs longer.

However, the size is not the only thing. A small, detailed design can have more stitches than a larger, simple outline design. That’s why stitch count is often a better way to guess the cost than just looking at the size.

What You Want Embroidered On

The item you pick makes a difference in the price. Putting a design on a flat, easy-to-hold polo shirt is different from putting it on a tricky spot on a jacket or a curved hat.

- Easy items: Polo shirts, t-shirts, sweatshirts, towels. These are flatter and simpler to put into the machine.

- Harder items: Hats (cost to embroider hats is often a bit higher), bags (with pockets or odd shapes), jackets (especially thick ones or in tricky spots like the back of the neck). These items take more time to set up on the machine. They might need special hoops or careful handling.

Because hats are so common, many shops have a set price for putting a logo on a hat. But generally, hats cost a bit more per design than a flat shirt.

How Many Items You Need

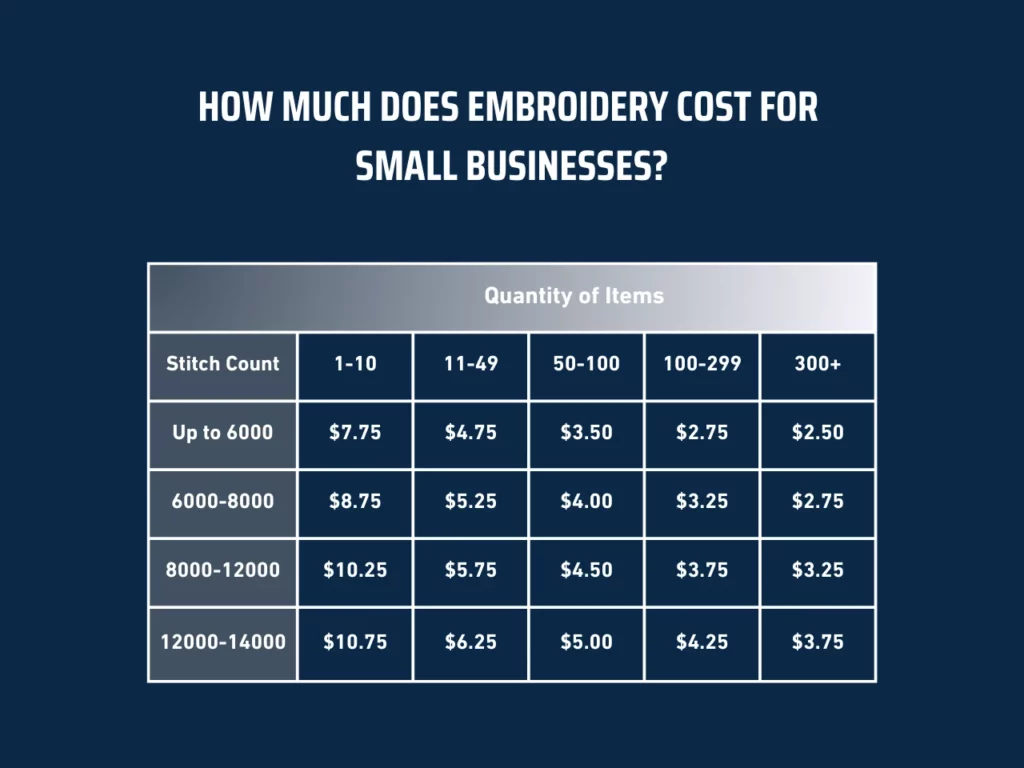

This is where commercial embroidery pricing comes in. If you need just one item embroidered, you pay a certain price. If you need 100 items, the price per item will go down a lot.

- Small orders: The shop has to set up the machine for your design. This setup takes time and effort. For one item, all that setup cost goes onto that single item.

- Large orders: The shop still has to do the setup. But that setup cost is spread out over many items. The machine runs for a long time once it starts. This is more efficient.

Think of it like baking one cookie versus baking 100 cookies. The time to preheat the oven and mix the dough (the setup) is roughly the same. But the time per cookie is much less when you bake many. So, the more items you order, the lower the average price for embroidery will be for each item.

Getting Your Picture Ready: Digitization

Before an embroidery machine can sew your design or logo, the design needs to be turned into a special file. This file tells the machine exactly where to put each stitch, what color thread to use, and in what order. This process is called digitization.

How much does it cost to digitize for embroidery? This is usually a one-time fee. You pay it the first time you get a specific design or custom logo embroidery cost. Once it’s digitized, the shop keeps the file. You won’t pay this fee again if you use the same design later.

- Digitization is not automatic. It takes a skilled person using special software.

- The person decides the best stitch types, directions, and density for your design. This makes the embroidery look good on the fabric.

- A poorly digitized design will look bad or might even damage the item.

So, the digitization fee pays for this skilled work. The cost varies based on the complexity of your design. A simple logo might cost less to digitize than a very detailed picture with many small parts. Prices for digitization can range from $25 for something very simple to $150 or more for complex designs. Some shops might offer free digitization if you order a very large number of items.

Special Threads or Fast Service

Do you want shiny metallic thread? Or glow-in-the-dark thread? These special threads can cost more than standard threads. They can also be harder for the machine to work with, sometimes leading to slower run times or more thread breaks.

Do you need your items finished very quickly? Most shops have a standard turnaround time (like 1-2 weeks). If you need your order faster than that, they might charge a rush fee. This is because they might have to stop working on other jobs to fit yours in.

Grasping Different Pricing Ways

Embroidery shops figure out your price using one or a mix of these methods. This is part of their embroidery pricing guide.

Paying Per Stitch

Many professional shops use this method. They count the stitches in your digitized design. They have a price for each stitch.

- Example: Your design has 10,000 stitches. The shop charges $0.005 per stitch.

- Calculation: 10,000 stitches * $0.005/stitch = $50.00 for the embroidery work on one item.

This price per stitch can go down as the total number of stitches goes up (volume discount on stitches). This is a common way to figure out the embroidery cost per stitch based on the design size and detail.

Paying Per Design Size

Some shops might simplify it. They put designs into size groups (like Small, Medium, Large). Each size group has a set price range.

- Example: A small chest logo (under 4 inches) costs $8-$12 per item. A large back design (up to 10 inches) costs $25-$40 per item.

This is easier for customers to understand upfront. The shop has already figured out the average stitch count for those sizes.

Paying Per Item

Sometimes shops just have a flat price to put a standard design on a specific item.

- Example: Putting your logo on any polo shirt is $10. Putting it on any hat is $12.

This is often for simple, common requests.

Paying a Flat Rate Per Order

This is less common for custom work, but some shops might give you one total price for your whole order (digitization + all the items).

The best way to know the actual cost is always to ask the shop for a custom quote. They will look at all the factors for your specific job. This is part of finding the average price for embroidery for your needs.

Cost Examples for Popular Items

Let’s look at what some common requests might cost. Remember, these are just rough ideas. Your actual price could be different based on all the factors we talked about.

Cost to Embroider Hats

Hats are very popular for logos. As mentioned, they can be a bit trickier than flat items.

- Typical cost per hat: Often ranges from $8 to $15 per hat for a standard front logo.

- Factors: The number of hats (bulk discounts apply heavily here), the stitch count of the logo, adding logos to the side or back, the type of hat (some are harder to hoop).

- Digitization: You’ll likely pay a one-time digitization fee for your logo, typically $40 – $80 for a standard logo.

So, if you ordered 12 hats with a standard logo, you might pay a digitization fee ($50) plus the price per hat (12 * $10 = $120). Total: $170. If you ordered 100 hats, the price per hat might drop to $7, making the cost 100 * $7 = $700 + $50 digitization = $750 total. The price per hat went from $10 to $7 because of the quantity.

Putting Designs on Shirts

Shirts (polos, t-shirts, button-ups) are probably the most common item for embroidery. They are usually easier to work with than hats.

- Small Chest Logo (like on a polo): Often costs $6 to $12 per shirt. Stitch counts are usually between 3,000 and 8,000 stitches.

- Large Back Design: Can cost $15 to $40 or more per shirt. These designs can have 20,000 to 50,000+ stitches.

- Factors: Quantity is key. Ordering 50 shirts costs much less per shirt than ordering 5. The type of shirt matters too (thick work shirt vs. thin t-shirt).

For custom logo embroidery cost on shirts, you’ll again have the one-time digitization fee for your logo. Then the price per shirt depends on the logo size, stitch count, and how many shirts you order.

Jackets, Bags, and Other Items

These items vary a lot.

- Jackets: Price depends on where the embroidery goes (chest, back, sleeve) and the jacket material/thickness. Back designs on jackets are common and cost more due to high stitch counts.

- Bags: Backpacks, duffels, totes. Cost depends on the size of the design and how easy the bag is to open and hoop. Pockets can get in the way.

- Patches: Embroidery shops can make embroidered patches. The cost depends on size, shape, stitch count, and if they add an edge (like merrowed).

Average Prices You Might See

Here is a simple table with some rough average price for embroidery. These are just ideas to give you a starting point. Prices can be higher or lower depending on your specific details and the shop you choose.

| Item Type | Design Size/Stitch Count Idea | Approx. Price Per Item (Lower Quantity, 1-12) | Approx. Price Per Item (Higher Quantity, 50+) | One-Time Digitization Fee (for a standard logo) |

|---|---|---|---|---|

| Hat (Front Logo) | Small/Medium (5k-8k stitches) | $10 – $15 | $7 – $10 | $40 – $80 |

| Polo Shirt | Small Chest (5k-8k stitches) | $8 – $12 | $5 – $9 | $40 – $80 |

| T-Shirt | Small Chest (5k-8k stitches) | $8 – $12 | $5 – $9 | $40 – $80 |

| Shirt/Jacket | Large Back (20k-40k stitches) | $25 – $40 | $18 – $30 | $60 – $150+ |

| Simple Patch | Small (under 3 inches) | $5 – $10 per patch (often with minimum order) | $3 – $7 per patch | $30 – $70 |

Note: The price per item shown here is after the one-time digitization fee is paid. If you only order one item, the total cost would be Digitization Fee + Price Per Item. If you order 100 items, the total cost would be Digitization Fee + (Price Per Item * 100). This shows how the price per item goes down with quantity.

Handling Commercial or Bulk Embroidery

Businesses, clubs, teams, and large groups often need commercial embroidery pricing. As we talked about, ordering in bulk makes the price per item much lower.

- Larger Orders = Lower Price Per Item: This is the main rule. Shops want big orders because they are more efficient. They pass some of those savings to you.

- Setup Cost Spread Out: The time and cost to set up the machine, hoop the first item, and get everything running perfectly is the same whether they run 1 item or 100. With 100 items, that setup cost is a tiny part of the price for each one.

- Material Costs: Shops buy threads and supplies in bulk, which is cheaper for them.

- Item Cost: If the embroidery shop is also providing the items (like the shirts or hats), they get better prices buying them in large quantities.

If you need many items, always ask for a bulk discount or pricing tier. Shops often have price breaks at certain numbers (like 12, 24, 48, 72, 100, 250, etc.).

How to Get Your Specific Price

The very best way to know how much your specific embroidery job will cost is to ask an embroidery shop for a quote. They need information from you to give you an accurate price.

Be ready to provide:

- Your Design: Send a clear picture or file of your logo or design. A good quality image helps them see the details.

- Design Size: Tell them how big you want the design to be (e.g., 3 inches wide for a chest logo, 10 inches tall for a back design).

- Colors: Tell them how many colors are in the design.

- Placement: Where on the item do you want the embroidery? (Left chest, center back, sleeve, hat front, etc.)

- Item Type: What are you putting it on? (Polo shirt, t-shirt, hat, jacket, bag, etc.). If you are providing the items, tell them what they are (brand, style number if possible).

- Quantity: How many of each item do you need?

With this info, the shop can figure out the stitch count (or estimate it), calculate the embroidery cost per item, add the digitization fee (if needed), and give you a total price. This is their embroidery service cost for your job.

Tips to Lower Your Embroidery Cost

Want to save some money on your embroidery order? Here are a few simple tips:

- Simplify Your Design: Fewer colors and less fine detail mean fewer stitches. This lowers the embroidery cost per stitch part of the price and might lower digitization cost too.

- Limit Colors: Try to use just one, two, or three colors if possible.

- Choose Common Items: Standard polo shirts and basic hats are often easier and cheaper to embroider than complex jackets or tricky bags.

- Order More Items: If you think you might need more later, ordering them all at once will almost always be cheaper per item than placing two smaller orders. This takes advantage of commercial embroidery pricing.

- Avoid Rush Orders: Plan ahead so you don’t have to pay extra fees for needing your items quickly.

- Check for Deals: Some shops might have specials on specific items or offer free digitization for large orders.

Wrapping Up Embroidery Costs

So, how much is embroidery? It’s not a simple number. It depends on the stitches, colors, size, item type, and especially how many items you order. There’s often a one-time fee to get your design ready for the machine (digitization). Shops might charge based on stitches, size, or per item.

The best way to know the price for your project is to contact an embroidery shop. Give them details about your design and what you need. They can give you a clear quote based on all the factors involved in their embroidery pricing guide and embroidery service cost. Knowing these factors helps you understand where the cost comes from and how you might be able to save money on your order.

Questions People Often Ask

Here are some common questions about embroidery costs.

Is the digitization fee a one-time cost?

Yes, almost always. You pay the digitization fee the first time you get a specific design or logo embroidered by a shop. They create the special file for their machines and keep it on hand. If you come back later and want the same design on more items, you usually don’t have to pay the digitization fee again.

Does a smaller design cost less?

Usually, yes. Smaller designs typically have fewer stitches than larger designs. Since stitch count is a major factor in pricing (embroidery cost per stitch), fewer stitches mean a lower cost for the embroidery work itself.

Is it cheaper to order a lot of items?

Definitely. The price per item goes down significantly when you order in bulk (like 24, 50, 100 items or more). The setup time and cost are spread over more items. This is the main idea behind commercial embroidery pricing.

Why do hats sometimes cost more than shirts?

Putting a design on a hat can be harder for the machine and takes more setup time than a flat shirt. Hats have curves and less area to work with easily. This extra effort is often reflected in the cost to embroider hats being slightly higher per item than on simple shirts.

Can I bring my own items to be embroidered?

Many embroidery shops allow this, but not all do. If you bring your own items, be aware that some shops might charge a bit more per item than if they provide the items. This can be because they can’t easily replace your item if something goes wrong during the embroidery process. Always ask the shop about their policy on customer-supplied goods as part of their embroidery service cost explanation.

How is the embroidery cost per stitch calculated?

The shop determines a base price for every 1000 stitches (or sometimes per single stitch, but that number is very small). They use their software to count the stitches in your digitized design. Then they multiply the total stitch count by their per-stitch rate. This gives the raw embroidery cost for one item based purely on the design’s complexity and size. Other factors like quantity and item type are then added or factored in.