What is digitizing an image for embroidery? Digitizing an image for embroidery means turning a picture or design into a special file. This file tells an embroidery machine how to sew the design. It maps out every stitch, color, and sewing order. Can I digitize an image for embroidery myself? Yes, you can learn to digitize images for embroidery. Many tools and resources are available. With practice, anyone can learn this skill. This guide will show you how. You will learn the steps needed to change your ideas into beautiful stitches.

Image Source: www.mrxstitch.com

Grasping Embroidery Digitizing

Digitizing is a key step in machine embroidery. It is the bridge between a picture and a stitched design. Without digitizing, your embroidery machine cannot sew a custom image. It is more than just pressing a button. It means guiding the machine. You choose stitch types. You decide stitch angles. You also set the sewing order. This makes your design look great when stitched. Good digitizing saves time and fabric. It also makes your finished piece shine.

Why Digitizing Matters

Digitizing is not just a technical process. It is an art form. A poorly digitized design can cause problems. It might fray. It might pucker the fabric. It might not look like the original picture. A well-digitized design runs smoothly. It looks crisp and clear. It shows off your work. This is why learning to digitize is so important. It gives you full control. You can make any design you wish.

Choosing Your Digitizing Tools

To digitize an image, you need special software. This embroidery digitizing software is your main tool. Many programs are available. Some are simple for beginners. Others are very advanced for pros. The best choice depends on your needs. It also depends on your budget.

Types of Software

Software comes in different types. Some are free. Some are paid. Paid software often has more features. It also gets more updates.

- Entry-Level Software: These programs are easy to use. They often have auto-digitizing features. They are good for simple designs. They are great for new users.

- Mid-Range Software: These offer more control. You can often choose stitch types. You can adjust densities. They are good for growing your skills.

- Professional Software: These are powerful tools. They give you full manual control. They are used by digitizing experts. They can handle complex designs.

Key Features to Look For

When you pick software, check its features.

- Auto Digitizing: This feature helps a lot. It converts images fast. It is good for quick starts.

- Manual Tools: You need to control stitches. Look for tools to draw lines. Look for tools to set fills.

- Stitch Types: Can you choose different stitches? Satin, fill, run stitches are common.

- Editing Options: Can you change stitch paths? Can you resize designs?

- File Formats: Does it save common embroidery files? (More on this later).

- User Interface: Is it easy to use? Can you find tools quickly?

- Support and Tutorials: Does the company offer help? Are there lessons to learn from?

Some popular software examples include Wilcom Hatch, Embrilliance, Embird, and many more. Do some research. Read reviews. Try demo versions if you can.

Preparing Your Image for Digitizing

Before you open your embroidery digitizing software, prepare your image. The quality of your original image matters a lot. A good image makes digitizing easier. A bad image makes it hard. It can even make your design look bad.

Image Quality and Resolution

Start with a clear picture. High resolution is best. This means many pixels. Pixels are tiny dots that make up an image. More pixels mean more detail. A blurry or pixelated image will be hard to trace.

- Crisp Lines: Make sure lines are sharp. Avoid fuzzy edges.

- Clear Colors: Colors should be distinct. No muddy blends.

- Simple Designs: For beginners, start simple. Less detail is easier to digitize.

- No Small Details: Embroidery machines have limits. Very tiny lines or text may not sew well. Remove them from your design.

Color Reduction for Embroidery

This is a very important step. Embroidery machines use thread. Each thread is one color. Your design might have many shades of a color. An embroidery machine cannot use hundreds of thread colors. You must reduce the number of colors.

How to reduce colors:

- Look at your image: See how many colors it has.

- Group similar shades: Light blue, medium blue, and dark blue might become just “blue.”

- Use a photo editor: Programs like GIMP or Photoshop can help. They have tools for color reduction.

- Simplify gradients: Smooth color changes are hard to stitch. Turn them into solid blocks of color.

- Aim for few colors: For simple logos, aim for 1-5 colors. For photos, maybe 10-15. Check your machine’s limits.

Reducing colors makes your design cleaner. It also makes the digitizing process easier. It saves you money on thread too.

The Digitizing Process: Step-by-Step

Now you have your clean image. You have your software ready. It is time to start digitizing. This is where you turn your picture into stitches.

Vectorizing Images for Embroidery

Many digitizers start with vector images. What is a vector image? It uses math to draw lines and shapes. It is not made of pixels. This means you can make it any size. It will never look blurry.

Raster vs. Vector Images:

- Raster Images (like photos): Made of tiny squares (pixels). When you make them bigger, they get blurry. JPG, PNG, GIF are common raster types.

- Vector Images (like logos): Made of points, lines, and curves. They stay sharp at any size. SVG, AI, EPS are common vector types.

Why is vectorizing images for embroidery important?

If your original image is raster (a photo), you might want to convert it. Many digitizing programs can trace raster images. But if you have a vector version, it is much easier. The software can often auto-convert vector lines into stitches. If you do not have a vector image, you will manually trace the raster image in your software.

Manual Embroidery Digitizing vs. Auto Digitizing

You have two main ways to digitize.

1. Auto Digitizing Embroidery Tips:

- This is the quickest way.

- The software tries to do all the work.

- You upload your image.

- The program finds shapes and colors.

- It then creates stitches automatically.

Pros of Auto Digitizing:

* Very fast.

* Easy for beginners.

* Good for simple designs.

Cons of Auto Digitizing:

* Less control over stitch quality.

* Can create too many stitches.

* May make designs look messy.

* Often needs manual fixes.

Tips for Auto Digitizing:

* Use very clean images. High contrast helps.

* Reduce colors beforehand.

* Always review the results. Fix any problems manually.

* Think of it as a starting point, not the final step.

2. Manual Embroidery Digitizing:

- This gives you full control.

- You draw every part of the design yourself.

- You choose stitch types.

- You set stitch directions.

- You control stitch density.

- You decide the sewing order.

Pros of Manual Digitizing:

* Best stitch quality.

* Efficient use of stitches.

* Designs sew smoothly.

* You learn how stitches work.

Cons of Manual Digitizing:

* Takes a lot of time.

* Requires more skill and practice.

* Can be hard for new users.

Most good digitizing combines both. You might auto-digitize a base. Then you use manual tools to clean it up. This saves time and gives good results.

Image to Stitch File Conversion

This is the core of digitizing. No matter if you use auto or manual tools, the goal is the same. You are telling the machine where to put each needle drop.

Key Concepts in Stitching:

-

Stitch Types:

- Run Stitch (or Walk Stitch): Simple lines. Like drawing with a pencil. Used for outlines or fine details.

- Satin Stitch: Thick, narrow stitches. They run side to side. Used for outlines, text, or small shapes. Gives a raised, shiny look.

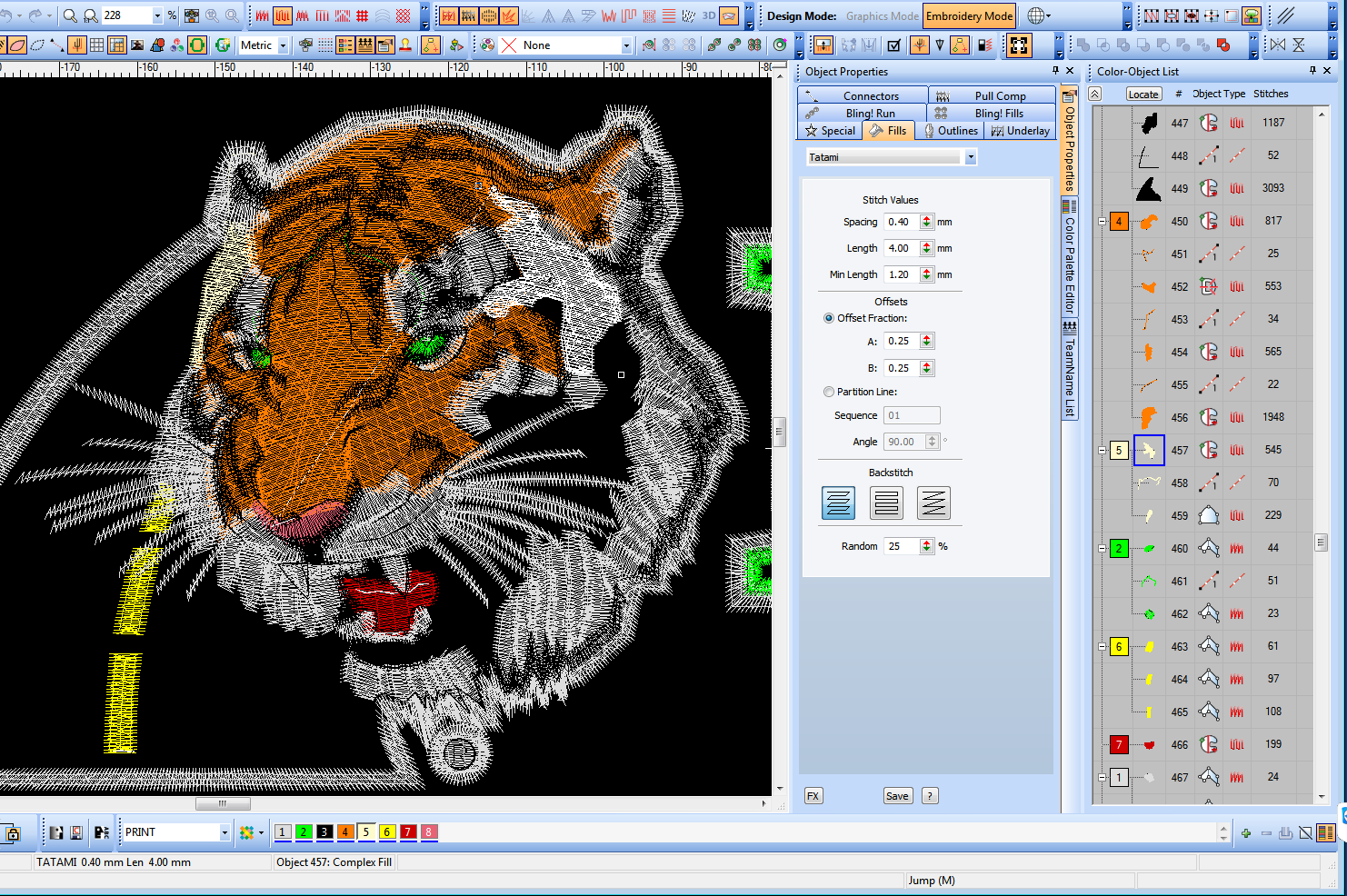

- Fill Stitch (or Tatami/Couching Stitch): Flat stitches. They cover large areas. Used for backgrounds or big shapes. They often look like woven fabric.

- Specialty Stitches: Appliqué, Redwork, Cross-stitch, etc.

-

Stitch Paths and Angles:

- Think of your design as shapes. Each shape needs stitches.

- Paths are the lines your needle follows.

- Angles are the direction of stitches. They help the design look smooth. They also help stitches lay flat. Change angles in curves. Change angles at corners.

-

Density:

- This is how close stitches are.

- High density means many stitches close together. This makes the design solid. It uses more thread. It can make fabric pucker.

- Low density means stitches are further apart. This looks lighter. It uses less thread. It is good for delicate fabrics.

- Finding the right density is key. It changes based on fabric and stitch type.

-

Pull Compensation:

- Fabric pulls and stretches when sewn. This changes the design shape.

- Pull compensation adds extra width to stitches. It makes shapes slightly bigger.

- This makes sure the design looks right after it is sewn. It helps lines meet up. It helps shapes stay true to size.

-

Underlay Stitches:

- These are unseen stitches. They go under the main stitches.

- They help stabilize the fabric. They prevent puckering.

- They give the top stitches something to grab onto.

- They make the design puff up a bit. This gives a richer look.

- Always use underlay for fill and satin stitches.

-

Connectors and Trims:

- When the machine moves from one part of the design to another, it might create a “jump stitch.”

- Connectors are short run stitches that link parts.

- Trims tell the machine to cut the thread. This gets rid of jump stitches.

- Too many trims slow down the machine. Too few trims make a messy design.

-

Sequencing:

- This is the order your design sews in.

- It is very important. Sew background first. Then mid-layers. Then outlines.

- Sewing order affects how colors lay. It affects how clean the design looks.

- It prevents parts from being covered up. It also helps reduce trims.

| Element | Purpose | Typical Stitch Type | Considerations |

|---|---|---|---|

| Outlines | Define shapes, add crispness | Run, Satin | Width, density, corners |

| Fills | Cover large areas with color | Fill (Tatami) | Stitch angle, density, underlay |

| Small Details | Fine lines, tiny text | Run, Satin | Min width (0.8mm for satin), detail level |

| Text | Lettering | Satin, Run | Size, font, stitch direction, spacing |

| Underlay | Stabilize fabric, build loft | Run, Zigzag | Always use for fills/satins; density and direction |

| Jump Stitches | Moves between design elements | Connectors/Trims | Minimize jumps, use trims carefully |

Specialized Digitizing Tasks

Some types of designs need special care.

Photo Embroidery Design

Making a photo embroidery design is challenging. You cannot just put a photo into a machine. It needs a lot of work.

- Simplify the Photo: Reduce colors drastically. Think of it more like a painting than a photo.

- Use Stitch Blending: Instead of solid blocks, use different stitch types. This can blend colors.

- Focus on Key Features: Do not try to capture every detail. Focus on faces, eyes, main objects.

- Use Light Densities: Often, lighter fill densities are used. This creates a softer, more artistic look.

- Experiment with Underlay: Special underlays can help build depth.

- Test, Test, Test: Sew out many versions. Change things. See what works.

It is often better to use a photo to inspire a drawing. Then digitize the drawing. This gives better results.

Custom Logo Digitizing

Custom logo digitizing is very common. Logos need to be precise. They must look the same every time.

- Precision is Key: Logos must be perfect. Lines must be straight. Circles must be round.

- Use Vector Art: Always start with the vector version of a logo if possible. This ensures sharpness.

- Readability: Small text or fine lines must be readable. Adjust sizes and stitch types.

- Color Matching: Match thread colors to brand colors exactly.

- Use Satin Stitches for Text: Most logo text uses satin stitch. This makes it bold and clear.

- Minimize Stitches: Efficient digitizing means fewer stitches. This saves time and thread. It also makes the logo durable.

- Test on Target Fabric: A logo on a polo shirt will digitize differently than on a hat.

Digitize Artwork for Machine Embroidery

When you digitize artwork for machine embroidery, you are changing art to thread.

- Interpret the Art: How will a brush stroke look in stitches? How will a pencil line translate?

- Simplify Complexities: Very detailed art needs simplifying. Break it into shapes.

- Choose Appropriate Stitches: Use different stitch types to show textures. Satin for smooth areas. Fill for large blocks. Run for fine lines.

- Layering and Depth: Plan your stitch layers. Create depth by sewing backgrounds first.

- Color Choices: Decide how many thread colors you will use.

- Artistic Vision: Your goal is to recreate the feel of the art. It will not be an exact copy.

Embroidery File Formats

Once your design is digitized, you save it. It must be in a format your embroidery machine can read. There are many embroidery file formats. Each machine brand often has its own preferred format.

- .DST (Tajima): A very common format. Most commercial machines use it. It holds stitch data but no color info. You often need a color sheet with it.

- .PES (Brother, Babylock, Bernina): Popular for home machines. It holds stitch data and color info.

- .JEF (Janome): Used by Janome machines. Holds stitch and color info.

- .HUS (Husqvarna/Viking): Used by Husqvarna/Viking machines.

- .EXP (Melco): Another common commercial format.

- .XXX (Singer, Compucon): Used by Singer machines.

- .VP3 / .VIP (Husqvarna/Viking, Pfaff): Newer formats for these brands.

- .CSD / .PCS (Pfaff): Older Pfaff formats.

- .EMB (Wilcom): This is a source file format. It contains all original design data. It is not for machines directly. You convert EMB to a machine format.

Always save your design in your machine’s format. If you share designs, save them in DST and PES. These are very common.

Tips for Better Digitizing

Practice makes perfect. Here are some tips to help you get better.

- Learn Your Software: Spend time exploring every tool. Watch tutorials.

- Start Simple: Do not try to digitize a complex photo first. Begin with basic shapes and text.

- Use Good Underlay: Always add underlay stitches. They are like the foundation of a house. They make your design strong.

- Check Stitch Angles: Make sure stitch angles follow the shape. This makes the design look smooth.

- Manage Density: Too dense, and it puckers. Too light, and it looks sparse. Adjust for fabric and thread.

- Factor in Pull Compensation: Your software will have this setting. Use it to prevent gaps.

- Reduce Color Count: Fewer thread changes save time. They also make the design cleaner.

- Minimize Jump Stitches: Plan your sewing order. This reduces thread cuts.

- Test on Fabric: Always sew a sample. Use the same fabric you will use for the final piece. This is the best way to check your work.

- Use the Simulate Feature: Most software has a stitch simulator. It shows how the design will sew. Use it before stitching.

- Keep a Log: Write down what worked and what did not. Note fabric type, settings, and results.

- Join Online Groups: Learn from others. Ask questions. Share your work.

- Invest in Quality Supplies: Good thread, needles, and stabilizers make a big difference.

The Importance of Testing

Testing your digitized design is not optional. It is crucial.

- Stitch out a sample: Use a scrap piece of the exact fabric you will use.

- Check for puckering: Does the fabric gather or pull?

- Look for gaps: Are there areas where the stitches do not meet?

- Check thread breaks: Does the machine keep stopping? This could mean bad digitizing.

- Examine outlines: Are they clean and sharp?

- Review density: Is it too thick or too thin?

- Check overall appearance: Does it look like your original vision?

Make changes in your software based on the test. Then, test again. Repeat until it is perfect. This step saves you from ruined projects. It saves you time and frustration.

Final Thoughts on Digitizing

Mastering how to digitize an image for embroidery takes time. It takes patience. But it is a very rewarding skill. You can turn any picture into a unique embroidered piece. You gain full control over your designs. From simple text to complex photo embroidery design, you can do it all. You can even create your own custom logo digitizing. You can digitize artwork for machine embroidery easily.

Remember to choose the right embroidery digitizing software. Always prepare your image well. Pay attention to color reduction for embroidery. Decide between manual embroidery digitizing and auto digitizing embroidery tips. Learn about vectorizing images for embroidery. Grasp the process of image to stitch file conversion. Know your embroidery file formats. Always test your designs. With every project, you will get better. Soon, you will be a digitizing master.

Frequently Asked Questions (FAQ)

Q1: How long does it take to learn to digitize an image for embroidery?

A1: Learning the basics can take a few days. Becoming good takes months or years. It depends on your practice. Start with simple designs first.

Q2: Do I need a special computer for digitizing software?

A2: Most digitizing software needs a good computer. Look for one with enough RAM (memory). A fast processor helps too. Check the software’s needs.

Q3: Can I digitize designs for different types of fabrics?

A3: Yes, but you need to adjust settings. Different fabrics need different stitch densities. They also need different underlay types. Practice on the fabric you will use.

Q4: Is it better to use manual digitizing or auto digitizing?

A4: Manual digitizing gives the best quality. It offers full control. Auto digitizing is faster. It is good for simple designs or quick starts. A mix of both is often best.

Q5: What is the most important part of digitizing?

A5: Many parts are important. But stitch quality and smooth sewing are key. This comes from good underlay, correct density, and proper stitch angles. Testing your design is also very important.