Winding a bobbin on a Singer sewing machine is a key skill. It helps you sew well. Many people ask, “What is a bobbin?” A bobbin is a small spool. It holds the bottom thread for your sewing machine. “Can I wind a bobbin without a machine?” No, most Singer machines need the machine’s help to wind a bobbin correctly. “Who is this guide for?” This guide is for anyone with a Singer sewing machine. It will teach you how to wind a bobbin. We will cover all the steps. You will learn to do it right every time.

A well-wound bobbin means smooth sewing. It stops many common problems. These include tangled threads or skipped stitches. Getting it right ensures your projects look great. Let’s start this important sewing journey together.

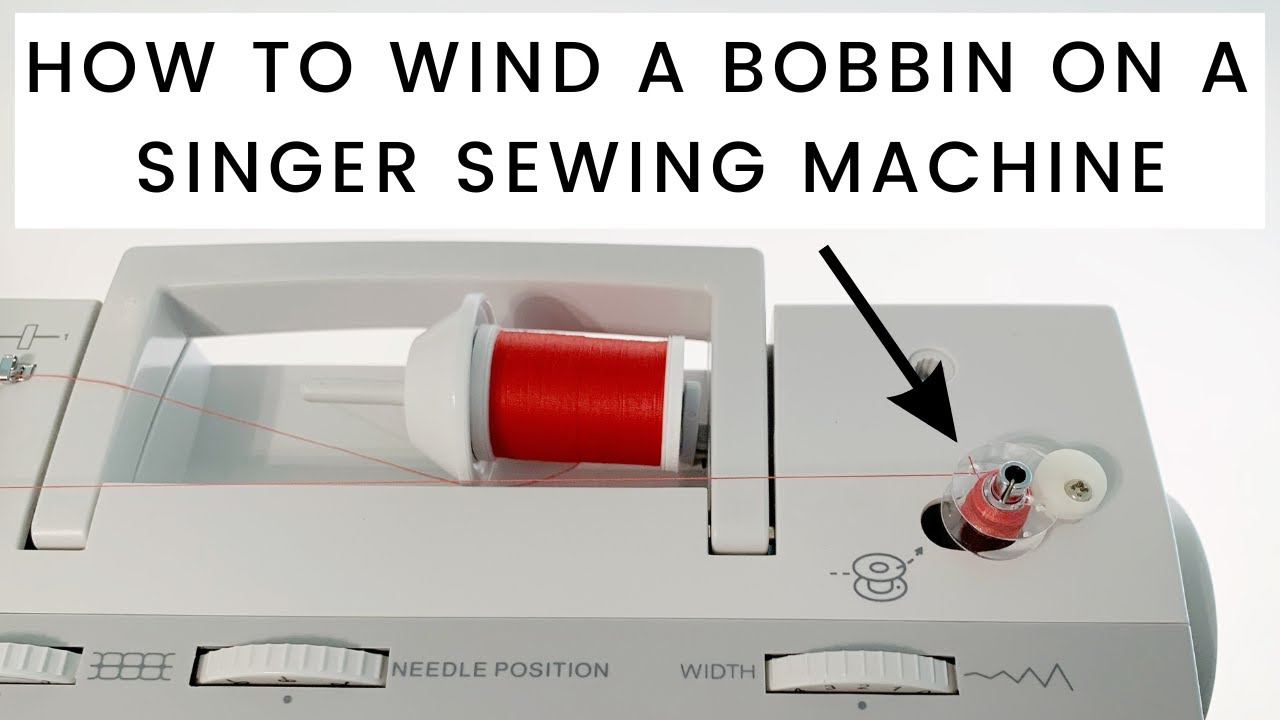

Image Source: i.ytimg.com

Getting Ready to Wind Your Bobbin

Before you wind, you need to set things up. This step is very important. It makes sure winding goes smoothly. It prevents problems later.

Necessary Tools and Supplies

You will need a few simple things. Make sure they are all ready.

- Your Singer Sewing Machine: It needs to be plugged in. Turn it on.

- An Empty Bobbin: Make sure it is the right type for your machine. Singer machines use different bobbin types. We will talk more about Singer sewing machine bobbin types later.

- A Spool of Thread: This is the thread you want on your bobbin. Pick a good quality thread.

- Scissors: You will need these to cut the thread.

Pre-winding Bobbin Setup

This is about getting your machine ready. Each step is simple. Follow them one by one. This helps make a perfect bobbin.

- Place Your Thread Spool: Put your thread spool on the spool pin. This is usually at the top of your machine. Make sure the thread unwinds easily. It should come off the spool smoothly.

- Raise the Presser Foot: Use the lever at the back of the needle area. Lift the presser foot up. This releases tension on the upper thread. It is a good habit to do this.

- Disengage the Needle: This is very important for safety. You do not want the needle moving. Most Singer machines have a handwheel. This is on the right side. You need to pull the handwheel out. Or, turn a small knob. This disconnects the needle bar. It stops the needle from moving up and down. Read your machine’s manual. It will show you exactly how to do this. This step prevents accidents. It also helps the machine focus power on bobbin winding.

The Bobbin Winding Process

Now, let’s wind the bobbin. This is the main part. We will go through each step carefully.

Locating the Singer Bobbin Winder Mechanism

Every Singer machine has a bobbin winder. It is usually on the top or front. Look for a small spindle. It sticks out. There might be a thread guide near it. This is your Singer bobbin winder mechanism. It is designed to make winding easy.

Placing the Empty Bobbin

Take your empty bobbin. Place it onto the bobbin winder spindle. This spindle is the small rod that spins. Push the bobbin down firmly. It should fit snugly. Make sure it clicks into place. Some bobbins have a small slot. This slot needs to line up with a pin on the spindle. This helps the bobbin spin with the spindle.

Threading for Winding

This step routes the thread. It goes from the spool to the bobbin. This path helps control the thread.

- First Thread Guide: Take the thread from your spool. Pull it to the first thread guide. This is often a small hook or loop. It is usually above the spool pin.

- Tension Disk: Now, wrap the thread around the bobbin winding tension disk. This is a small metal disk or set of disks. It controls the thread tension for bobbin winding. Correct tension is key. It makes a neatly wound bobbin. Wrap the thread around it once or twice. Make sure the thread sits firmly in the disk. If the tension is too loose, your bobbin will be loose. If it is too tight, the thread might break.

- Through the Bobbin Hole: Find the small hole on your bobbin. It is usually on one side. Push the end of the thread through this hole. Push it from the inside out. Pull about 3 to 4 inches of thread through. This tail helps start the winding.

- Wrap the Thread: Wrap the thread tail around the bobbin. Wrap it a few times clockwise. This secures the thread to the bobbin. It stops it from slipping when you start.

Engaging the Bobbin Winder

You need to move the bobbin into place. This allows it to wind.

- Slide the Bobbin: Push the entire bobbin winder spindle to the right. It should click into place. This lines up the bobbin with the winding mechanism. It also often presses the bobbin against a rubber wheel. This wheel spins. It makes the bobbin spin.

- Cut the Thread Tail: Hold the thread tail that came out of the bobbin hole. Hold it gently. Do not pull too hard.

Starting the Winding

Now, you are ready to wind.

- Press the Foot Pedal: Gently press your foot pedal. The bobbin will start to spin. The thread will begin to wind onto the bobbin.

- Watch the First Few Wraps: As it starts, watch the thread. Make sure it is winding smoothly. The thread tail you were holding can be cut after a few turns. It should be trapped under the new windings. Cut it close to the bobbin.

- Regulate Speed: Start slowly. Then, you can press the pedal more. Let the bobbin wind. Most Singer machines have an automatic bobbin winding feature. This means the bobbin will stop winding when it is full. This is a great feature. It stops you from overfilling the bobbin.

Stopping the Winding

When the bobbin is full, the automatic bobbin winding feature will activate.

- Machine Stops: The bobbin winder will stop spinning on its own. This happens when the thread reaches a certain level. It means the bobbin is full.

- Manual Stop: If your machine does not have an automatic stop, watch the bobbin. Stop when it looks full. Do not overfill it. An overfilled bobbin can cause problems. It can make the thread stick. It might not fit in the bobbin case.

- Cut the Thread: Use your scissors. Cut the thread connecting the bobbin to the spool. Leave a small tail on the bobbin.

- Disengage the Bobbin: Slide the bobbin winder spindle back to the left. This releases the bobbin.

- Remove the Bobbin: Take the newly wound bobbin off the spindle.

You now have a perfectly wound bobbin. Good job!

Solutions for Winding Problems

Sometimes, things do not go as planned. Do not worry. We can fix most issues. This section covers common bobbin winder troubleshooting.

Uneven Bobbin Winding Solutions

An uneven bobbin is a common issue. The thread might pile up on one side. Or, it might be loose in places. This can cause trouble when you sew. It can lead to tangled thread in the bobbin case.

- Check Thread Path: Is the thread going through all the guides? Is it wrapped correctly around the tension disk? A thread that is not in the right path will wind unevenly. Go back and re-thread the bobbin winder mechanism.

- Verify Tension: The thread tension for bobbin winding is very important. If the thread is too loose, the bobbin will wind very loosely. This often looks lumpy. If it is too tight, the thread might break. It can also wind too tightly, causing the bobbin to be hard and uneven. Make sure the thread is snug in the tension disk.

- Inspect the Bobbin Winder Spindle: Is the bobbin sitting correctly on the bobbin winder spindle? Is it wobbling? If the bobbin is not firm on the spindle, it can wind unevenly. Check for lint or debris. Clean the spindle area.

- Try a Different Bobbin: Sometimes, the bobbin itself is the problem. It might be bent or damaged. Try a new, empty bobbin. Make sure it is the right type for your Singer machine.

- Consistent Speed: Try to press the foot pedal evenly. Starting and stopping too much can make the winding uneven. A steady speed is best.

Other Common Issues

Here are other problems you might face.

- Thread Breaks During Winding:

- Reason: Tension is too high.

- Fix: Check the tension disk. Make sure the thread is not caught. It should move freely. Use good quality thread. Old or weak thread breaks easily.

- Bobbin Does Not Spin:

- Reason: The bobbin winder is not engaged. Or, the handwheel is not disengaged.

- Fix: Push the bobbin winder to the right firmly. Make sure the handwheel is pulled out or set to winding mode. Check your machine’s manual.

- Bobbin Overfills or Underfills:

- Reason: The automatic stop feature is not working. Or, it is not set right.

- Fix: If your machine has an auto-stop, check for lint. Lint can block the sensor. If no auto-stop, you must watch it. Stop when it looks full. Do not fill it past the edges.

- Thread Slipping on Bobbin:

- Reason: You did not secure the thread tail well enough.

- Fix: Make sure to thread through the bobbin hole. Then wrap the thread around the bobbin a few times. Hold the tail for the first few turns. Then cut it.

These bobbin winder troubleshooting tips should help you solve most problems.

After Winding: Inserting Your Bobbin

You have wound a perfect bobbin. Now you need to put it in the machine. This is called inserting bobbin into case. Singer machines have two main types of bobbin cases: top-loading and front-loading.

Top-Loading Bobbin Case

Many newer Singer models have top-loading bobbins. These are often easier to use. The bobbin drops in from the top. You can usually see it under a clear cover.

- Open the Bobbin Cover: This is usually a clear plastic slide plate. It sits on the sewing machine bed. Slide it open.

- Orient the Bobbin: Hold your wound bobbin. Check which way the thread unwinds. For most top-loading Singer machines, the thread should unwind counter-clockwise. This means it comes off the top to the left. Some machines are different. Check your manual.

- Place the Bobbin: Drop the bobbin into the bobbin case. Make sure it sits flat.

- Guide the Thread: Find the thread slot. This is usually a small groove or notch. Pull the bobbin thread through this slot. It should go under a small metal spring or guide. This creates tension.

- Pull and Cut: Pull the thread gently. It should come out easily. Pull about 4-6 inches of thread. Let it hang out.

- Close the Cover: Slide the bobbin cover plate back into place.

Front-Loading (Vertical) Bobbin Case

Older Singer models and some newer ones have front-loading bobbins. These use a separate metal bobbin case. This case goes into a shuttle hook area.

- Remove the Bobbin Case: Open the front access cover of your machine. This is usually near the needle plate. Pull out the bobbin case. It often has a small latch or handle.

- Insert Bobbin into Case: Hold the bobbin case. Take your wound bobbin. Place it inside the bobbin case.

- Thread the Bobbin Case: Find the small slot on the side of the bobbin case. It looks like a long groove. Pull the bobbin thread into this slot. Then, pull it under the tension spring. This is a flat metal piece on the case. The thread should slip under it. It should feel snug.

- Check Tension (Optional but Helpful): Hold the bobbin case by the thread. Let the case hang. If the tension is good, the case will drop slowly, a little bit at a time. If it drops fast, it is too loose. If it stays put, it is too tight. You might need to adjust a tiny screw on the bobbin case for tension. This is rare for winding issues but good to know.

- Reinsert the Bobbin Case: Hold the bobbin case by its latch. Push it back into the machine’s shuttle hook area. It should click into place. Make sure it is fully seated.

- Close the Cover: Close the front access cover.

- Bring Up Bobbin Thread: This step is for all machines. Hold the top thread (from the needle). Turn the handwheel toward you. Turn it one full turn. The needle will go down and then come back up. As it comes up, it should catch the bobbin thread. It will pull a loop of bobbin thread up.

- Pull the Loop: Use a pin or your fingers. Grab the loop of bobbin thread. Pull it all the way through the needle plate hole.

- Place Threads: Pull both the top thread and the bobbin thread under the presser foot. Lay them towards the back of the machine.

Now your bobbin is in place. You are ready to sew.

Singer Sewing Machine Bobbin Types

Not all bobbins are the same. Singer machines use different kinds. Using the wrong bobbin can cause big problems. It can lead to bad stitches. It can even damage your machine.

It is very important to use the correct type. Check your machine’s manual. It will tell you the right bobbin type.

Here are some common Singer sewing machine bobbin types:

| Bobbin Type | Description | Common Singer Models | Material | Notes |

|---|---|---|---|---|

| Class 15 | Flat on both sides. Standard size. | Many modern machines, older 66, 99 | Plastic, Metal | Very common. Check if “J” (plastic) or “L” (metal) is specified. |

| Class 66 | Slightly domed top and bottom. Looks like a small hat. | Older 66, 99, 201 models | Metal | Specific to certain older Singer machines. |

| Class 15J | Similar to Class 15. Made of clear plastic. | Newer Singer models (e.g., Simple, Tradition, Quantum Stylist) | Plastic | Often clear for viewing thread supply. Do not use metal Class 15. |

| Class 2000 | Wider and flatter than Class 15. | Some industrial or specific models | Plastic | Less common for home machines. |

| Class 93/221 | Very small, thin bobbins. | Featherweight 221, 222 | Metal | Specific to the Featherweight. |

Always use the bobbin type listed in your machine’s manual. A Class 15 bobbin will not work in a machine that needs Class 66. They are different sizes. They will not fit right. This causes problems with tension and stitch quality. Plastic bobbins often do not work in machines meant for metal bobbins. Metal bobbins can scratch the bobbin case on machines designed for plastic.

Mastering Bobbin Thread Winding Tips

Winding a bobbin is a skill. You get better with practice. Here are some extra bobbin thread winding tips. They will help you wind perfect bobbins every time.

Tip 1: Use Good Quality Thread

Cheap thread can cause issues. It can break easily. It can fray. This leads to uneven winding. Good quality thread winds smoothly. It gives a nice, even stitch.

Tip 2: Do Not Overfill or Underfill

- Overfilling: A bobbin that is too full can stick in the bobbin case. It can jam the machine. It can also cause thread breaks. Most machines with an automatic bobbin winding feature will stop at the right time. If yours does not, stop when the thread is just below the bobbin’s edge.

- Underfilling: A bobbin that is not full enough means you run out of thread quickly. This interrupts your sewing. Wind it as full as your machine allows.

Tip 3: Check Your Machine’s Manual

Your Singer machine manual is your best friend. It shows exact threading paths. It tells you about specific features. Always check it first if you are unsure.

Tip 4: Clean Your Machine Regularly

Lint and dust build up. They can get into the bobbin winder mechanism. They can affect the tension disks. This causes uneven winding or thread breaks. Use a small brush to clean the bobbin winder area. Do this often.

Tip 5: Match Bobbin and Spool Thread

For most sewing, you should use the same type and weight of thread for both the top and bobbin. This ensures balanced stitches. Sometimes you use special bobbin thread. This is for specific tasks like embroidery. But for regular sewing, match them.

Tip 6: Hold the Thread Firmly at the Start

When you first start winding, hold the thread tail. Hold it gently. Do not let it slip. Once a few layers are on the bobbin, you can cut the tail. This prevents tangles at the start.

Tip 7: Practice Makes Perfect

The more you wind bobbins, the easier it gets. You will learn the feel of the right tension. You will know how your machine works. Do not get discouraged if your first few bobbins are not perfect.

Automatic Bobbin Winding Feature: A Closer Look

Many modern Singer sewing machines have an automatic bobbin winding feature. This makes winding very simple.

How It Works

- Sensor: These machines have a small sensor. It detects when the bobbin is full.

- Auto-Stop: When the thread reaches the sensor, the machine stops winding. This prevents overfilling.

- Consistency: This feature helps ensure every bobbin is wound to the same fullness. This leads to more consistent stitches.

Benefits

- Ease of Use: You do not have to watch the bobbin constantly.

- No Overfilling: It stops at the perfect level. This means fewer jams.

- Time-Saving: Just set it and let it go.

Troubleshooting the Automatic Feature

If your automatic bobbin winding feature is not working, here are things to check:

- Lint or Debris: A small piece of lint can block the sensor. Clean the bobbin winding area carefully. Use a small brush or a can of compressed air.

- Incorrect Threading: If the thread is not in the correct path, the sensor might not detect it. Re-thread the bobbin winding path.

- Damaged Bobbin: A damaged bobbin might not sit correctly. This can stop the sensor from working. Try a new bobbin.

- Machine Settings: Make sure your machine is set to the bobbin winding mode. Some machines have a separate switch. Others rely on disengaging the handwheel.

Using the automatic feature correctly saves you time and effort. It helps you get back to sewing faster.

Final Thoughts on Bobbin Winding

Winding a bobbin is a basic sewing skill. But it is very important. It sets the stage for all your sewing projects. A well-wound bobbin means less frustration. It means better stitch quality.

Remember these key points:

- Preparation is Key: Get all your supplies ready. Set up your machine right. Disengage the needle for safety.

- Correct Threading: Follow the thread path exactly. The tension disk is crucial for good winding.

- Right Bobbin Type: Always use the correct Singer sewing machine bobbin types. This cannot be stressed enough.

- Troubleshoot: If things go wrong, use our bobbin winder troubleshooting tips. Most problems are simple fixes.

- Practice: The more you do it, the better you get.

With this guide, you have the knowledge. You can wind perfect bobbins every time. Enjoy your sewing!

Frequently Asked Questions (FAQ)

Q1: Why is my bobbin thread loose even after winding it?

A1: Your bobbin thread is loose likely due to low thread tension for bobbin winding. Make sure the thread is wrapped firmly around the bobbin winding tension disk. If it slips, the bobbin will wind loosely. Also, check that the bobbin is pushed fully onto the bobbin winder spindle.

Q2: Can I use pre-wound bobbins with my Singer machine?

A2: Yes, many Singer machines can use pre-wound bobbins. However, make sure they are the correct Singer sewing machine bobbin types for your machine. Also, check the thread type. Pre-wound bobbins often have a lighter-weight bobbin thread. This is for specific uses.

Q3: My bobbin winder mechanism is making a strange noise. What should I do?

A3: A strange noise often means friction or blockage. Check the Singer bobbin winder mechanism for lint or thread bits. Clean the area well. A tiny drop of sewing machine oil (if your manual suggests it) might help a metal spindle. If the noise continues, your machine might need service.

Q4: How do I know which way the bobbin thread should unwind when inserting it?

A4: For top-loading bobbins, the thread usually unwinds counter-clockwise. This means it comes off the top to the left. For front-loading bobbins, it varies. Always check your specific Singer machine manual. It will show a clear diagram for inserting bobbin into case.

Q5: My bobbin isn’t winding evenly. What are some quick fixes?

A5: For uneven bobbin winding solutions, first check your thread path. Make sure the thread is properly engaged in the tension disk. Also, ensure the bobbin is seated firmly on the bobbin winder spindle. Sometimes, simply re-threading and trying again fixes the issue. Make sure your spool of thread is not catching.